Shanghai University

Article Information

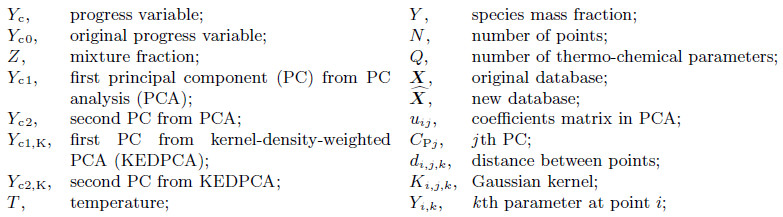

- Jing CHEN, Minghou LIU, Yiliang CHEN. 2015.

- Optimizing progress variable definition in flamelet-based dimension reduction in combustion

- Appl. Math. Mech. -Engl. Ed., 36(11): 1481-1498

- http://dx.doi.org/10.1007/s10483-015-1997-7

Article History

- Received Mar. 15, 2015;

- Revised May 9, 2015

1 Introduction

1 Introduction

Involving many species and elementary reactions, combustion is a complex system with large dimensions and a wide range of time scales. Meanwhile, partial differential equations for combustion simulation are usually high coupled and hard to be solved numerically. Simulating the whole composition space spatially and temporally is a huge challenge. Thus, the dimension reduction models that can reduce dimensionality and stiffness are very necessary. Up to present, proposed models can be divided into two types. The first type is to simplify the chem- ical reaction mechanism directly by deleting the unimportant species and elementary reactions, such as the sensitivity analysis[1, 2], the direct relation graph (DRG)[3], the path flux analysis (PFA)[4], the quasi-steady-state-approximation (QSSA)[5], and the partial equilibrium approximation (PEA)[6] methods. The second type focuses on the state-space parameterization, where the whole thermo-chemical state space is assumed to be parameterized by a few reduction parameters. Flamelet-based combustion models just fall into this type, e. g. , the flamelet/progress variable (FPV)[7], the flamelet generated manifolds (FGM)[8], and the flame prolongation of intrinsic low-dimensional manifolds (ILDM) (FPI)[9]. These models are based on the laminar flamelets, which can involve the diffusion effects in the dimension reduction and have achieved a lot of success in turbulent combustion simulation[10, 11, 12, 13, 14]. In these models, the mixture fraction and progress variable[7, 15] are usually selected as the “reduction parameters”. Mathematically, this is similar to the eigenvalue analysis in linear spaces, and the mixture fraction and the progress variable are corresponding to the two largest eigenvalues.

The progress variable (Yc) is usually defined as a linear combination of the species mass fractions (e. g. , Yc = YCO + YCO2 + YH2 + YH2O[15] or Yc = YCO + YCO2[16]), and the selection of the species set and coefficients is more or less intuitive. Although widely used, this kind of definitions is questionable especially in the cases with fuel pyrolysis. This kind of definitions is reasonable for one-step global reaction while its performance for the detailed chemical mechanism needs more evaluation. Recently, the optimization approaches to define progress variables more rigorously have been proposed. Ihme et al. [17] proposed a formal method for the generation of the reaction progress variable. Based on the constraint that the progress variable must be a strictly monotonic function of the “progress parameter”, they built up an optimization problem and got the optimal definition of the progress variable. Via a comparison of the cost functions in methane/air and n-heptane/hydrogen/air combustion systems, better performances of the new proposed method can be observed. Unfortunately, the database they analyzed was limited to simple diffusion and partially premixed flames, and they did not apply this kind of definitions to a flow solver or computational fluid dynamics (CFD). Niu et al. [18] also proposed an optimization-based approach to get the automated progress variable definition[19, 20]. However, they only applied their method on the one-dimensional (1D) premixed flames with different initial conditions and perfectly mixed canonical problems while the extension to multiple parameters and CFD applications needs to be preformed.

Based on the eigenvalue analysis, the principal component analysis (PCA)[21, 22] and its variants are rigorous mathematical tools, and can lead to the systematic methods to identify the low-dimensional manifolds, to propose new reduced dimension approaches, and to define the progress variables. Parente et al. [23, 24] identified low-dimensional manifolds via conducting a global PCA and two local PCA models, i. e. , the vector quantization PCA and the mixture fraction PCA. In order to use the manifolds identified by the PCA, the principal component (PC)-score approach was proposed[25], where the transport equations for few PCs were solved directly. However, the source terms in these equations remain a challenge and many works lay stress on it[26, 27]. Coussement et al. [28] conducted simulations coupling manifolds and the flow solver. They proposed a method called the manifold generated by the local PCA (MG- L-PCA), and computed a hydrogen flame-vortex interaction with a DNS solver. In this work, the flamelet that contains manifolds is used to train the approach to obtain the coefficient matrix to reconstruct the retained PCs in the CFD. The PCA is also able to define new progress variables. Najafi-Yazdi et al. [29] provided a rigorous mathematical formulation for flamelet-based models, and got the minimum number of the linearly independent progress variable definition based on the PCA. However, its verification in coupling the flamelets and flow solver is not conducted, either. Coussement et al. [30] proposed the KEDPCA approach, and found that it reconstructed the flame front more accurately by weakening the influence of the over-representation of some hot or cold areas. Mirgolbabaei et al. [31] proposed a nonlinear PCA for the combustion composition space, and they found that the approach yielded a good reconstruction of the composition space based on two PCs. It is noted that the database utilized in many studies is from the direct numerical simulation (DNS) or experimental measurement of a specific combustion field, while the works focusing on optimizing the definitions of the progress variables by use of the laminar flamelet data have not been done much yet. Considering the fact that the DNS of a specific combustion device is hard while the corresponding laminar flamelets are easy to be obtained, it is more imperative and constructive to conduct the PCA of the flamelets data instead of the DNS data. In the PC-score method, the laminar flamelets help to train the method in order to reconstruct the retained variables in the flow solver. In the chemistry tabulation method, laminar flamelets can be used to build the chemistry table.

It is noted that the above works can be classified to the priori works because they rely on the existing DNS or experimental data. Up to the present, the numerical simulation of a combustion field based on the optimized progress variable definition is rare in the literature. In view of this point, the performance of the optimized progress variable definition in coupling the laminar flamelets and the flow solver is evaluated in the current paper. A CH4/N2/air laminar lift-off flame, which has a feature of triple-flame and is characterized by both diffusion and premixed processes, is chosen for the study. The DNS of the flame is conducted, and the reconstructions or simulations using the conventional progress variable and the optimized progress variable from the PCA are compared. The KEDPCA approach[32, 33] is also adopted here to weaken the over-representation of some extreme states. Taking the characteristics of these flamelets into consideration, a bi-variable kernel density is used instead of the monovariable and the full-variable kernel densities in the KEDPCA. In this situation, the selection of these two variables is carefully made. Quantitative comparisons between these methods and their validations are provided. Meanwhile, the criteria for this optimization are proposed and discussed. A one-to-one relation between the tabulated variables and these progress variables is verified.

2 Theoretical calculations 2. 1 PCA and KEDPCA of flameletsThe PCA is based on orthogonal transformation, through which the possibly correlated variables in a database can be converted into a set of values of linearly independent variables called PCs. The first PC has the largest possible variance accounting for the variability in the database as much as possible, and each succeeding PC has the highest possible variance under the constraint that it is orthogonal to the preceding PCs.

Laminar flamelets as a whole are set as the database here, and some details in this PCA process are shown briefly. Let φ = [Y1, Y2, ··· , YQ]T be the thermo-chemical state of one point in one flamelet, and then take N representative points φ1, φ2, ··· , φN, which cover all the flamelets and constitute a database (X). If

which represents the mean value of the database, the fluctuating value φ′ = φ− φx= [Y1 ′ , Y2 ′ , ···, Y Q′ ]T can be obtained. This process is called “centering” and is widely adopted in the PCA. Here, Yi is the mass fraction of the ith species, and Q is the number of the species. Due to the fact that the mixture fraction and the widely used conventional progress variable are both defined as the linear combinations of mass fractions, only mass fractions appear in φ and the temperature and pressure are neglected here. Thus, the “scaling” process appeared in the PCA to make the variance of each variable is not necessary here. Another reason to neglect this process is that too many PCs are needed to reconstruct the database if scaling is adopted[30], which makes it difficult to employ practically in the chemistry tabulation method. When the PCA is applied on this database, PCs can be obtained by

where the subscript “i” refers to the species i, and the subscript “j” refers to the j th PC. PCs are in fact weighted linear combinations of species mass fractions, which is consistent with the progress variables[17, 18, 29] in mathematical forms. Thus, these PCs can be regarded as the optimized progress variables. PCs can be used to reconstruct the original database (laminar flamelets) while they can also represent the thermo-chemical state in the turbulent combustion since the turbulent combustion can be viewed as an ensemble of a series of laminar flamelets[7, 10, 15]. Considering all these conditions, the first few PCs obtained from the PCA approach are used to define the progress variables.

The classical PCA approach is sensitive to the database. Meanwhile, cold or hot areas in a combustion field are often over-represented in the classical PCA approach[30]. In this situation, the KEDPCA is appreciated. In the KEDPCA, the kernel and the corresponding weight are computed with a presumed kernel function, and the original database is multiplied by the weight before applying the PCA. Here, the Gaussian radial basis function (RBF) kernel[34] is used as the kernel function. In the multi-variables case, the distance for the kth variable between the current point j and another point i is computed by

The Gaussian kernel Ki, j, k is given by

where hk is the bandwidth associated with the kth variable. Then, the density for this variable is

For the point j, the global density Kj is computed from all the variables’ densities,

and the corresponding weight Wj is

Once the weight is obtained, the original matrix (database) X is multiplied by the associated weight matrix before the PCA,

and the new matrix  is used for the computation of the covariance matrix in the PCA. It

is noted that the bandwidth for each variable affects the last weight a lot, and the optimal

bandwidth can be regarded as a function of the standard deviation[35] as follows:

is used for the computation of the covariance matrix in the PCA. It

is noted that the bandwidth for each variable affects the last weight a lot, and the optimal

bandwidth can be regarded as a function of the standard deviation[35] as follows:

Coussement et al. [30] showed that this kind of bandwidth is close to the so-called “optimized bandwidth” in the combustion issue. In the KEDPCA, full-variable kernel density computation, i. e. , adopting all Q variables in (6), yields two issues when the Q variables are applied on a combustion database, in which the computing cost can be high when the large database is considered, and a multi-variable kernel density can lead to erroneous evaluation of the weights due to the nature of combustion. This is why it is worth investigating if the number of variables can be reduced. In Ref. [30], the mono-variable (only temperature) is adopted, and the results show that this is a good reduction. However, the characteristics of the database and the target flame to reconstruct are different here. Consider that various flamelets are used to form the database. Thus, it is reasonable to use “reduction parameters” instead of full-variables or only temperature because “reduction parameters” are able to represent the evolution of the thermo-chemical state space. In this situation, two kinds of “reduction parameters” can be used, i. e. , mixture fraction and conventional progress variables or two optimized progress variables obtained from the classical-PCA forming two new bi-KEDPCA approaches denoted as the “hybrid-KEDPCA” and the “pre-KEDPCA”, respectively. The hybrid-KEDPCA, the preKEDPCA, and the classical PCA are all adopted in the current paper, and the performances of these three models are compared in Section 3.

2. 2 Details of testing processA testing process to evaluate the performance of the optimized progress variable in a combustion simulation is shown in Fig. 1 in detail. According to the conditions of a given combustor, various laminar premixed flamelets can be obtained and form a database. The database can be mapped as a function of the mixture fraction (Z) and the conventional progress variable (denoted as “Yc0”) and forms the traditional Z-Yc0 chemistry-table. Moreover, the PCA of the database is conducted, and the first two PCs can be used to define the optimized progress variables denoted as Yc1 and Yc2. The reason why two PCs are selected is shown in Subsection 3. 2. In the KEDPCA, the kernel density is calculated (e. g. , calculated based on Z-Yc0 in the “pre-KEDPCA”) and leads to two new PCs denoted as Yc1, K and Yc2, K. Then, the database is mapped to these new parameters and forms the new premixed chemistry-tables: PCA-table and KEDPCA-table. Meanwhile, the DNS of the combustion field can be performed to offer the spatial and temporal thermo-chemical data (“T , Yi all fields” in Fig. 1). Based on these data, the reduction parameters in the combustion field (“Yc1, Yc2 fields” and “Z, Yc0 fields” in Fig. 1) can be used to look up the corresponding chemistry table to obtain the reconstructed data. Then, the DNS data and the reconstructed data are compared to evaluate the performance of different reduction parameters.

|

| Fig. 1 Flow chart of testing proces |

A CH4/N2/air lift-off laminar flame is selected in the present study. This multi-regime flame is dominated by a triple-flame which consists of a lean premixed branch, a rich premixed branch, and a non-premixed diffusion flame branch. The burner configuration can be found in Fig. 10 in Ref. [36]. The flame is studied experimentally and numerically[36, 37, 38] and has been proved to be reproduced well by the premixed flamelets in the chemistry tabulation method[36] which are also adopted herein. The fuel CH4/N2 stream flows through the central jet with a cold air coflow. The mixture fraction is equal to 1 in the fuel stream and 0 in the coflow, and the stoichiometric mixture fraction is 0. 098. The detailed inlet parameters are given in Table1. Although the flame looks like a diffusion-kind flame from Table1, it is essentially dominated by the triple flame. The main reason is that the inlet velocities of the fuel stream and the oxidizer flame are both sufficiently small, leaving the streams adequately premixed before the triple point[39]. In the DNS, one 2D mesh with 800×200 grids in the axial and radial directions is adopted and the minimum grid size is about 0. 005 mm to satisfy the requirement of DNS[40]. The chemical kinetic mechanism GRI-1. 2[41] with 21 species and 84 reactions is selected, and the transport coefficients are computed by the CHEMKIN library[42]. In the DNS, 20 scalar equations for all the species except N2 are solved in addition to the continuity equation, the momentum equations, and the energy equation.

|

| Fig. 10 Plots of T in cases: (a) reconstruction using Yc1,K and Yc2,K and (b) reconstruction using Yc1 and Yc2 |

Note that the definition of the mixture fraction herein is related to the chemical elements. Bilger et al. [43] deduced the definition of the mixture fraction based on the conservation of the element mass, which can be applied on not only the non-premixed flames but also the premixed flames. In the CH4/O2 case (no matter how much N2 is added in the fuel or the oxidizer side), the definition is

where W is the molecular weight of the corresponding atom or molecule (C, H, or O2), f is the element mass fraction, the subscript “F” stands for the fuel inlet side, and the subscript“O” stands for the oxidizer inlet side. For example, fC, F stands for the carbon element mass fraction on the fuel inlet side. The element mass fractions can be calculated as

leading to the fact that the mixture fraction can be rewritten as

which is consistent with the definition of the optimized progress variables (see (2)). The coefficients αij mean the weight fraction of the jth element in the ith species and are related to the fuel.

2. 3 Criteria for optimizationFor the definition of the progress variable, some basic principles must be satisfied[17, 18]:

(a) The transport equation for the progress variable should be conveniently solved in the CFD.

(b) The reactive scalars from which the progress variable is constructed should all evolve on comparable time scales.

(c) All parameters that define the manifold should be independent of one another.

(d) The set of parameters from which the manifold is formed should uniquely characterize each point in the thermo-chemical state space.

(e) The progress variable should monotonically evolve when progressing from the fresh gas to the burnt gas along the chemical trajectories, i. e. , a one-to-one relation between the progress variable and the tabulated variable.

(f) The species concentrations should not vary too rapidly versus the progress variable, i. e. , the gradients in the progress variable direction should be finite.

If the progress variable is defined as (2) in the PCA/KEDPCA approach, it is easy to find that the principles (a) and (c) are fulfilled. As to the principle (b), this is a strong constraint, and the time scale analysis will be taken into account in the future work. There are some common points between the principles (d) and (e), and the verifications of these are shown in Subsections 3. 1 and 3. 2. As for the so called “optimize” in the present work, some criteria are proposed:

(i) In the progress variable definition, the artificial factor should be reduced.

(ii) The turning points or the most important feature (e. g. , flame front) should be fully represented.

(iii) The progress variable definition should not be too sensitive to the database.

(iv) When all the above criteria are fulfilled, the progress variable should account for as much of the variability in the database as possible.

It is obvious that the optimized progress variable definitions based on the PCA fulfill Criteria (i) and (iv), while the KEDPCA approach fulfills all these four criteria. Criterion (iv) ranks last since it is hard to judge in some conventional definitions. Another advantage of the optimized definition based on the PCA is that this kind of definition needs little detailed chemistry knowledge.

3 Results and discussion 3. 1 Verification of monotonical evolvementWhether the optimized progress variable definition or the conventional definition is satisfied, Principle (e) is verified here. The 1D freely propagating premixed flamelets of CH4/N2/air, CH4/air, C3H8/air, C7H16/air with the equivalence ratio (φ) covering the flammability zone are analyzed. Each single flamelet is arranged in φ(Yc), where φ stands for the thermo-chemical variables, and Yc is a progress variable. Two conventional definitions Yc = YCO + YCO2 , Yc = YCO + YCO2 + YH2 + YH2O and the definition based on the first PC are compared. The results show that this principle is fulfilled in the PCA case and the Yc = YCO + YCO2 + YH2 + YH2O case. While in the Yc = YCO + YCO2 case, this is not followed when the equivalence ratio is slightly greater than one (φ ∈ [1. 3, 1. 5]). Figure2 shows the T profiles along with the progress variables in the premixed flamelets with φ = 1. 3, illustrating that this one-to-one relation is not followed for Yc = YCO + YCO2 , where sometimes one Yc maps to two temperature values. This phenomenon also results in a very large value of derivative (near maximum Yc), and the principle (f) is not ensured which is stressed in Ref. [18]. This is avoided when the progress variable is defined by the other two methods. The verification shows that the optimized progress variable obtained from the PCA can guarantee the monotonicity in the 1D flamelets case.

|

| Fig. 2 T profiles along with progress variables in different premixed flamelets where φ = 1.3, and Yc is normalized by its maximum value for comparison |

To decouple the flow/chemistry interactions in the lift-off flame, various premixed flamelets with different initial equivalence ratios (in the range of the lean flammability limit φ = 0. 5 and the rich flammability limit φ = 2. 0) are used to establish the chemistry tables. The thermo-chemical states out of the limits are usually obtained by linear extrapolation in the chemistry tabulation methods (e. g. , FGM): extrapolation between the oxidizer state and the lean flammability limit and extrapolation between the fuel state and the rich flammability limit. The number of the interpolated data is selected artificially and does not affect the final Z-Yc0 chemistry table too much. However, the PCA is sensitive to the database, and some states may be over-represented. For instance, in one premixed flamelet, ignition may occur very fast, and many points fall into cold or hot before or after ignition[30]. These cold or hot states will be over-represented. Meanwhile, the extrapolation between the flammability limit and the oxidizer (or fuel) state will change the database and affect the PCA approach too. In view of this point, the KEDPCA is adopted here to weaken this “over-representation” and sensitivity. Here, the premixed flamelets, the fuel state (CH4/N2), and the oxidizer state (air) are chosen to form the database first. Then, the PCA gives the definitions of the first two PCs (Yc1, K and Yc2, K) (see Table2). This table also shows the first two PCs (Yc1, K and Yc2, K) obtained from the hybrid-KEDPCA. The first two PCs obtained from the pre-KEDPCA are almost the same as those from the hybrid-KEDPCA and are not shown here. Different from the conventional definition of the progress variable, the PCA results show that the reactants (CH4 and O2) also play an important role in the definition. In the chemical reaction mechanism, N2 and Ar do not react, and they can be removed from the definitions. These optimized progress variable definitions are based on the specific database, and in other flames or burners, the definitions may differ more or less, i. e. , there is no general expression for the progress variable. In the PCA/KEDPCA approach, only when the absolute value of one species’ coefficient ui, j is larger than 0. 01, it is adopted to define the PCs. Plots (not shown here) compared with PCs defined by all species indicate that the influence of the omitted coefficients and species is very small.

The reason why only two PCs are used to optimize the progress variables is shown here. Figure3 gives the reconstruction of these premixed flamelets when two PCs are adopted in the PCA approach. Major species CH4, CO2, and H2O are reconstructed well, and the plots are almost the same as shown in Fig. 3(a) (R2 statistics R2>0. 9). Minor species like CO and H2 are reconstructed with deviations (Fig. 3(b), R2∈[0. 5, 0. 9]), and OH performs the worst as shown in Fig. 3(c) (R2=0. 41). This is consistent with the results obtained by Parente et al. [23] where more PCs are needed in the OH and NO case. When more PCs are used as the reduction parameters, i. e. , when p increases, the reconstruction of OH performs better as shown in Fig. 4. The reconstruction of OH is perfect when p is equal to 6. It is noted that R2>0. 82 when p > 3. However, using so many PCs leads to large computation loads and numerical errors in the chemistry tabulation. Increasing of the cost outweights the actual benefits. Meanwhile, Table3 gives a quantitative comparison of the reconstruction with different p. The contribution rates which are widely used as indications of the performance of reconstruction are shown here, and it is worth noting that when one PC is used, only a small part of the sample feature is recovered; when two PCs are chosen, the reconstruction is quite good; three PCs give a better performance, however, the improvement is not obvious. Therefore, in the CFD, it is reasonable and effective to use two PCs.

|

| Fig. 3 Reconstructed flamelets compared with original data when p = 2, where solid line stands for state that original data equal recovered data, and discrete point set stands for real states |

|

| Fig. 4 Changes of YOH reconstruction performance when p increases, where solid line stands for state that original data equal recovered data, and discrete point set stands for real states |

Once the progress variables are defined, the tabulation of thermo-chemical variables can be

made. Figure5 shows the temperature and OH mass fraction contour plots as functions of Z-Yc0 (Yc0=YCO+YCO2+YH2+YH2O) in the Z-Yc0-table or Yc1-Yc2 in the PCA-table, respectively.

It shows that in the 2D space original flamelets, the sample forms a triangular region, and two

kinds of tables show some similarities. Large values of OH are confined to a narrow area, and

it can be predicted that this would bring numerical errors when looking up the tables. The

methods to decrease the OH derivative (i. e. , to extent the OH areas) are imperative. It is noted

that the OH near the border of the high-area in Fig. 5(b) is much more continuous than that

in Fig. 5(d). In the process of building these libraries, the fact that every point in the thermochemical state-space is uniquely characterized by two optimized progress variables can be found

which fulfills Principle (d). Meanwhile, the gradients in the PCA-table  have the

same order of magnitude as those in the Z-Yc0 -table, which proves that the progress variable

based on the PCA performs at least consistently with the conventional progress variable with

respect to Principle (f). As to one single premixed flamelet, the verification of the monotonicity

shows that the one-to-one relationship between the thermo-chemical variables and the optimized

progress variables shown in Table2 is guaranteed. The conclusion in Subsection 3. 1 can also be

drawn here. However, more complex cases are still in need to verify these optimized progress

variables in view of Principles (d) and (e).

have the

same order of magnitude as those in the Z-Yc0 -table, which proves that the progress variable

based on the PCA performs at least consistently with the conventional progress variable with

respect to Principle (f). As to one single premixed flamelet, the verification of the monotonicity

shows that the one-to-one relationship between the thermo-chemical variables and the optimized

progress variables shown in Table2 is guaranteed. The conclusion in Subsection 3. 1 can also be

drawn here. However, more complex cases are still in need to verify these optimized progress

variables in view of Principles (d) and (e).

|

| Fig. 5 Plots of T and OH in premixed Z-Yc0-table (a,b) and PCA-table (c,d) |

The performance of different methods in reconstruction of the lift-off flame is shown in this section. Figure6 shows the comparison of the temperature contour plots from five methods. Figure6(a) gives the DNS result and is regarded as a benchmark. Figure6(b) gives the result obtained by looking up the KEDPCA-table using Yc1, K and Yc2, K in the hybrid-KEDPCA approach, and the results in the pre-KEDPCA approach are almost the same (not shown here). Figure6(c) gives the result obtained by looking up the PCA-table using Yc1 and Yc2. Figure 6(d) gives the result by looking up the Z-Yc0-table using Z and Yc = YCO+YCO2 +YH2 +YH2O. Figure6(e) gives the result from the same table but using Z and Yc = YCO+YCO2 . It is obvious that Figs. 6(b) and 6(c) give the best reconstructed plots, especially in the high temperature region. Although not as well as the PCA approaches, the conventional reduction parameters can mostly recover the temperature field and reproduce the flame characters. To show the performance of these methods more clearly, Fig. 7 shows the comparison of the OH contour plots. The conclusions from Fig. 6 can also be drawn here. The method with the conventional reduction parameters over-estimates OH a lot while the PCA and KEDPCA approaches give better results. However, the discontinuity in the plots of Figs. 7(b) and 7(c) (especially near the border at r = 0. 005 m) is displayed, and this is believed to be closely associated with the feature of the narrow area in Fig. 5(d). Meanwhile, different Yc0 definitions (see Figs. 7(d) and 7(e)) show some deviation.

|

| Fig. 6 Plots of T in cases: (a) DNS, (b) reconstruction using Yc1,K and Yc2,K, (c) reconstruction using Yc1 and Yc2, (d) reconstruction based on Yc = YCO + YCO2 + YH2 + YH2O, and (e) reconstruction based on Yc = YCO + YCO2 |

|

| Fig. 7 Plots of OH in cases: (a) DNS, (b) reconstruction using Yc1,K and Yc2,K, (c) reconstruction using Yc1 and Yc2, (d) reconstruction based on Yc = YCO + YCO2 + YH2 + YH2O, and (e) reconstruction based on Yc = YCO + YCO2 |

To give a more intuitive comparison of these methods, Figs. 8 and 9 show the recovered temperature and OH mass fraction as functions of the DNS results. As shown in Fig. 8, the temperatures are under-estimated too much in the high temperature area (T > 1 800 K) when using Z and Yc0 as the reduction parameters. In Fig. 8, the temperature is captured well in general while in Fig. 9, OH is always over-estimated even in the PCA approach. This indicates that it is difficult to reconstruct OH well using only two reduction parameters. In Fig. 9(b), some sharp shapes are loomed just like the discontinuity in Fig. 7. The results from the two conventional progress variables share a lot of similarities (see Figs. 8(c) and 8(d) and Figs. 9(c) and 9(d)), while Figs. 8(a) and 8(b) and Figs. 9(a) and 9(b) give the best results, especially in the high temperature zone.

|

| Fig. 8 Recovered T as function of original one in cases: (a) reconstruction using Yc1,K and Yc2,K, (b) reconstruction using Yc1 and Yc2, (c) reconstruction based on Yc = YCO+YCO2 +YH2 +YH2O, and (d) reconstruction based on Yc = YCO + YCO2 , where solid line stands for state that original data equal recovered data, and discrete point set stands for real states |

|

| Fig. 9 Recovered OH as function of original one in cases: (a) reconstruction using Yc1,K and Yc2,K, (b) reconstruction using Yc1 and Yc2, (c) reconstruction based on Yc = YCO+YCO2 +YH2 +YH2O, and (d) reconstruction based on Yc = YCO + YCO2 , where solid line stands for state that original data equal recovered data, and discrete point set stands for real states |

Another flamelet database is investigated here to show the advantage of the KEDPCA approach. In this new database, 5 extrapolation states are added between the rich flammability limit and the fuel state. The temperature plots from the hybrid-KEDPCA and the PCA approaches are shown in Fig. 10. It is found that temperature in the flame base (y < 0. 005 m) of Fig. 10(b) is unreasonable due to the added 5 extrapolation states, meaning that the distribution near the fuel side is wrongly captured while this error is avoided in the KEDPCA approach. The maximum temperature deviation in the flame base is about 900 K. Both two kinds of bi-KEDPCAs perform well, which indicates that KEDPCA is more robust.

To show the accuracy of reconstruction, the R2 statistics for different species of these meth- ods are shown in Table4. It is obvious that the reconstruction based on the PCA/KEDPCA method gives better performance than the mixture fraction/conventional progress variable for all species. Two bi-KEDPCA approaches slightly outperform the PCA approach for most species except for the intermediate species OH, H, and O. Table4 gives many important species, and other species that perform like CO and lead to the same conclusions are not shown. The difference between the PCA approach and the KEDPCA approach is small compared with the difference between the conventional definitions and the PCA approach. Two kinds of conventional progress variables perform almost the same. T , CO2, H2O, and H2 are always reconstructed well while OH, CO, and CH2O are much harder to be reproduced well. In general, all PCA/KEDPCA methods perform well to predict these minor species. These results show the promise for the ability to use the optimized progress variable definition in the flamelet-based models.

The optimizing progress variable definition in the flamelet-based dimension reduction in combustion is conducted. The PCA and KEDPCA are applied on the premixed flamelet database, leading to the optimized progress variable definition based on the first two PCs. The validation of these definitions is conducted via the reconstruction of a CH4/N2/air lift-off flame. Bivariables are used to calculate the kernel density in the KEDPCA, and these two variables can be regarded as the mixture fraction/conventional progress variable or two optimized progress variables obtained from the PCA. In this way, two kinds of hybrid-KEDPCA approaches can be obtained. The reconstruction of the lift-off flame shows that the optimized progress variables perform better than the conventional ones. The contour plots of the recovered T and OH reflect that the progress variables based on the PCA perform much better in the high temperature area. The R2 statistics show that the hybrid-KEDPCA approach performs slightly better than the PCA except for some minor species. The main advantage of the KEDPCA is that this approach can be affected little by the extrapolation of the database, while the PCA sometimes leads to irrational distributions. Meanwhile, the criteria for this optimization are proposed and discussed.

| [1] | Rabitz, H., Kramer, M., and Dacol, D. Sensitivity analysis in chemical kinetics. Annual Review of Physical Chemistry, 34, 419-461 (1983) |

| [2] | Lutz, A. E., Kee, R. J., and Miller, J. A. Senkin: A Fortran Program for Predicting Homogeneous Gas Phase Chemical Kinetics with Sensitivity Analysis, Sandia National Laboratories, Livermere (1988) |

| [3] | Lu, T. and Law, C. K. A directed relation graph method for mechanism reduction. Proceedings of the Combustion Institute, 30, 1333-1341 (2005) |

| [4] | Sun, W., Chen, Z., and Gou, X. A path flux analysis method for the reduction of detailed chemical kinetic mechanisms. Combustion and Flame, 157, 1298-1307 (2010) |

| [5] | Rao, C. V. and Arkin, A. P. Stochastic chemical kinetics and the quasi-steady-state assumption: application to the gillespie algorithm. The Journal of Chemical Physics, 118, 4999-5010 (2003) |

| [6] | Rein, M. The partial equilibrium approximation in reacting flows. Physics of Fluids, A: Fluid Dynamics, 4, 873-886 (1992) |

| [7] | Pierce, C. D. and Moin, P. Progress-variable approach for large-eddy simulation of non-premixed turbulent combustion. Journal of Fluid Mechanics, 504, 73-97 (2004) |

| [8] | Vreman, A., Albrecht, B., and van Oijen, J. Premixed and nonpremixed generated manifolds in large-eddy simulation of sandia flame d and f. Combustion and Flame, 153, 394-416 (2008) |

| [9] | Gicquel, O., Darabiha, N., and Thévenin, D. Liminar premixed hydrogen/air counterflow flame simulations using flame prolongation of ILDM with differential diffusion. Proceedings of the Combustion Institute, 28, 1901-1908 (2000) |

| [10] | Bilger, R. W., Pope, S. B., and Bray, K. N. C. Paradigms in turbulent combustion research. Proceedings of the Combustion Institute, 30, 21-42 (2005) |

| [11] | Vegendla, S. N. P. and Hasse, C. Steady flamelet progress-variable (FPV) modeling and simulation of a high-pressure gasifier. Energy and Fuels, 27, 7772-7777 (2013) |

| [12] | Vegendla, S., Messig, D., and Weise, S. Flamelet-based time-scale analysis of a high-pressure gasifier. Energy and Fuels, 25, 3892-3899 (2011) |

| [13] | Yilmaz, B., Ozdogan, S., and Gokalp, I. Numerical study on flame-front characteristics of conical turbulent lean premixed methane/air flames. Energy and Fuels, 23, 1843-1848 (2008) |

| [14] | Albrecht, B., Zahirovic, S., and Bastiaans, R. A premixed flamelet-PDF model for biomass combustion in a grate furnace. Energy and Fuels, 22, 1570-1580 (2008) |

| [15] | Ihme, M. and See, Y. C. LES flamelet modeling of a three-stream mild combustor: analysis of flame sensitivity to scalar inflow conditions. Proceedings of the Combustion Institute, 33, 1309- 1317 (2011) |

| [16] | Vervisch, L., Hauguel, R., and Domingo, P. Three facets of turbulent combustion modelling: DNS of premixed v-flame, LES of lifted nonpremixed flame and RANS of jet-flame. Journal of Turbulence, 5, 1-8 (2004) |

| [17] | Ihme, M., Shunn, L., and Zhang, J. Regularization of reaction progress variable for application to flamelet-based combustion models. Journal of Computational Physics, 231, 7715-7721 (2012) |

| [18] | Niu, Y. S., Vervisch, L., and Tao, P. D. An optimization-based approach to detailed chemistry tabulation: automated progress variable definition. Combustion and Flame, 160, 776-785 (2013) |

| [19] | Farcy, B., Abou-Taouk, A., Vervisch, L., Domingo, P., and Perret, N. Two approaches of chemistry downsizing for simulating selective noncatalytic reduction DeNOx process. Fuel, 118, 291-299 (2014) |

| [20] | Ribert, G., Vervisch, L., and Domingo, P. Hybrid transported-tabulated strategy to downsize detailed chemistry for numerical simulation of premixed flames. Flow, Turbulence and Combustion, 92, 175-200 (2014) |

| [21] | Abdi, H. and Williams, L. J. Principal component analysis. Wiley Interdisciplinary Reviews: Computational Statistics, 2, 433-459 (2010) |

| [22] | Moore, B. Principal component analysis in linear systems: controllability, observability, and model reduction. IEEE Transactions on Automatic Control, 26, 17-32 (1981) |

| [23] | Parente, A., Sutherland, J. C., and Tognotti, L. Identification of low-dimensional manifolds in turbulent flames. Proceedings of the Combustion Institute, 32, 1579-1586 (2009) |

| [24] | Parente, A., Sutherland, J., and Dally, B. B. Investigation of the mild combustion regime via principal component analysis. Proceedings of the Combustion Institute, 33, 3333-3341 (2011) |

| [25] | Sutherland, J. C. and Parente, A. Combustion modeling using principal component analysis. Proceedings of the Combustion Institute, 32, 1563-1570 (2009) |

| [26] | Isaac, B., Parente, A., Smith, P., Fru, G., and Thevenin, D. Source term parameterization for PCA combustion modelling. Proceedings of the European Combustion Meeting, Lund University Press, Sweden (2013) |

| [27] | Biglari, A. and Sutherland, J. C. A filter-independent model identification technique for turbulent combustion modeling. Combustion and Flame, 159, 1960-1970 (2012) |

| [28] | Coussement, A., Gicquel, O., and Parente, A. MG-local-PCA method for reduced order combustion modeling. Proceedings of the Combustion Institute, 34, 1117-1123 (2013) |

| [29] | Najafi-Yazdi, A., Cuenot, B., and Mongeau, L. Systematic definition of progress variables and intrinsically low-dimensional, flamelet generated manifolds for chemistry tabulation. Combustion and Flame, 159, 1197-1204 (2012) |

| [30] | Coussement, A., Gicquel, O., and Parente, A. Kernel density weighted principal component analysis of combustion processes. Combustion and Flame, 159, 2844-2855 (2012) |

| [31] | Mirgolbabaei, H., Echekki, T., and Smaoui, N. A nonlinear principal component analysis approach for turbulent combustion composition space. International Journal of Hydrogen Energy, 39, 4622- 4633 (2014) |

| [32] | Schlkopf, B., Smola, A., and Mjller, K. R. Nonlinear component analysis as a kernel eigenvalue problem. Neural Computation, 10, 1299-1319 (1998) |

| [33] | Parzen, E. On estimation of a probability density function and mode. Annals of Mathematical Statistics, 33, 1065-1076 (1962) |

| [34] | Schlkopf, B., Tsuda, K., and Vert, J. P. Kernel Methods in Computational Biology, MIT Press, Cambridge (2004) |

| [35] | Silverman, B. W. Density Estimation for Statistics and Data Analysis, CRC Press, Boca Raton, Florida (1986) |

| [36] | Jha, P. K. and Groth, C. P. T. Tabulated chemistry approaches for laminar flames: evaluation of flame-prolongation of ILDM and flamelet methods. Combustion Theory and Modelling, 16, 31-57 (2011) |

| [37] | Bennett, B. A. V., Mcenally, C. S., Pfefferle, L. D., and Smooke, M. D. Computational and experimental study of axisymmetric coflow partially premixed methane/air flames. Combustion and Flame, 123, 522-546 (2000) |

| [38] | Schwer, D. A., Lu, P., and Green, W. H., Jr. An adaptive chemistry approach to modeling complex kinetics in reacting flows. Combustion and Flame, 133, 451-465 (2003) |

| [39] | Ray, J., Najm, H, N., and Mildne, R. B. Triple flame structure and dynamics at the stabilization point of an unsteady lifted jet diffusion flame. Proceedings of the Combustion Institute, 28, 219-226 (2000) |

| [40] | Grtzbach, G. Spatial resolution requirements for direct numerical simulation of the RayleighBWnard convection. Journal of Computational Physics, 49, 241-264 (1983) |

| [41] | Smith, G. P., Golden, D. M., and Frenklach, M. GRI-MECH: an Optimized Detailed Chemical Reaction Mechanism for Methane Combustion, Sandia National Laboratories Report, SAND-898009B, New Mexico (1999) |

| [42] | Kee, R. J., Rupley, F. M., and Meeks, E. Chemkin-III: a FORTRAN Chemical Kinetics Package for the Analysis of Gas-phase Chemical and Plasma Kinetics, Sandia National Laboratories, New Mexico (1996) |

| [43] | Bilger, R. W., Starner, S. H., and Kee, R. J. On reduced mechanisms for methane air combustion in nonpremixed flames. Combustion and Flame, 80, 135-149 (1990) |

2015, Vol. 36

2015, Vol. 36