Shanghai University

Article Information

- Limei CAO, Xinhui SI, Liancun ZHENG. 2016.

- Convection of Maxwell fluid over stretching porous surface with heat source/sink in presence of nanoparticles:Lie group analysis

- Appl. Math. Mech. -Engl. Ed., 37(4): 433-442

- http://dx.doi.org/10.1007/s10483-016-2052-9

Article History

- Received Jun. 5, 2015;

- in final form Oct. 22, 2015

The studies on convective heat transfer have received great attention because of its wide applications in energy related engineering problems. Furthermore,a great number of investigations on nanofluid show that the nanoparticles in fluids can improve the thermal conductivity of these fluids. The studies on nanofluids have been reviewed by Eastman et al.[1],Kakac and Pramaumjaroenkij[2],and several others. These reviews discussed in detail the work done on convective transport in nanofluids. Boungiorno[3] considered the different theories to explain the enhanced heat transfer characteristics of nanofluids. Kuznetsov and Neid[4] studied the natural convective flow of a nanofluid over a vertical plate. In addition,they later extended the work to a nanofluid saturated porous medium[5]. In Ref. [6],Makinde and Aziz investigated the boundary layer flow of a nanofluid past a stretching sheet with a convective boundary condition. Following these works,Ramesh and Gireesha[7] considered the effects of heat source/sink on the steady boundary layer flow of a Maxwell fluid over a stretching sheet with the convective boundary condition in the presence of nanoparticles.

The boundary layer flow behaviors of non-Newtonian fluids have also attracted much interest due to the large number of practical applications in industrial and manufacturing processes. Because of the complexity of these fluids,there is not a single constitutive equation which exhibits all properties of such non-Newtonian fluids[8, 9, 10, 11, 12, 13]. For example,some non-Newtonian fluid models cannot predict the effects of elasticity. However,the Maxwell model,a subclass of non-Newtonian fluids,which can predict the stress relaxation,has become more popular[14, 15]. Noor[16] presented analysis of the magnetohydrodynamic (MHD) flow of a Maxwell fluid past a vertical stretching sheet in the presence of thermophoresis and chemical reactions. Liu et al.[17] studied the time periodic electroosmotic flow (EOF) of generalized Maxwell fluids between two microparallel plates and presented an analytical solution of EOF velocity. Hayat et al.[18] obtained an analytic solution for the unsteady MHD flow in a rotating Maxwell fluid through a porous medium. Nadeem et al.[19] analyzed the heat transfer of a Maxwell fluid past a stretching sheet.

Many of the above works have been done by the self-similar analysis theory. The classical method for finding similarity reduction of nonlinear differential equations is the Lie group method of infinitesimal transformations. It reduces the number of independent variables of the partial differential equations under consideration and keeps the system and associated initial and boundary condition invariant. A special form of Lie group transformations,known as the scaling group transformation,is the most powerful,sophisticated,and systematic method to generate similarity transform and is widely used in nonlinear dynamical systems,especially in the field of deterministic chaos[20, 21] and different flow phenomena[22, 23, 24, 25, 26, 27, 28]. For example,Asghar et al.[22] discussed the steady three-dimensional flow and heat transfer of viscous fluid on a rotating disk stretching in the direction by radial Lie group theory symmetries. Abd-el-Malek et al.[25] applied the Lie group method in studying nonlinear inviscid flows with a free surface under gravity. Hamad[27] studied the effect of a magnetic field on the free convection flow of a nanofluid over a linear stretching by the scaling group of transformations.

Motivated by the above works,in this paper,we present a general procedure for applying the one-parameter group of transformations to the problem of the convection of a Maxwell fluid over a stretching porous surface with the heat source/sink in the presence of nanoparticles. As a result,we obtain the similarity transformation by the Lie group analysis. Furthermore, since most of the nanoparticle parameters are included in the temperature and concentration distribution equations,we discuss the effects of such physical parameters on the temperature and the concentration in detail.

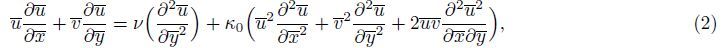

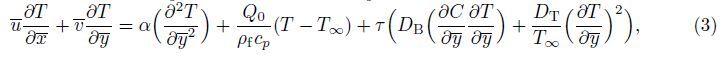

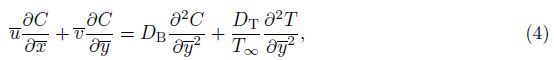

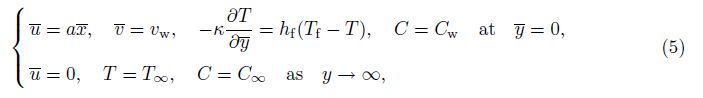

2 PreliminariesConsider a two-dimensional steady incompressible fluid flowing past a stretching porous surface with the convective boundary condition. In addition,the influence of heat source/sink and nanoparticle is considered,while the sheet is stretching from the plane $\bar y$ = 0. The flow is assumed to be confined to $\bar y$ > 0. Two equal and opposite forces are applied along the x-axis so that the sheet is stretched. The temperature of the sheet surface is the result of a convective heating process which is characterized by a temperature Tf and a heat transfer coefficient hf . Then,the boundary layer equations of Maxwell fluid along nanoparticles in the presence of heat source/sink are given as follows[29]:

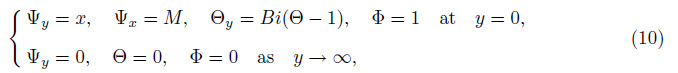

The appropriate boundary conditions for the physical problem are

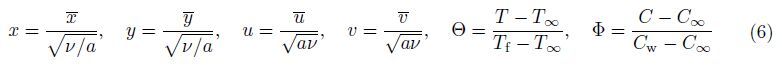

Introducing the following non-dimensional variables:

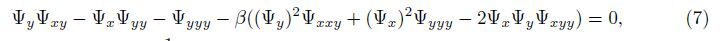

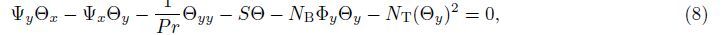

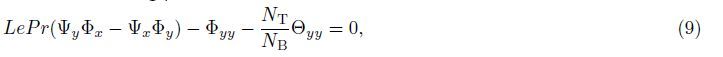

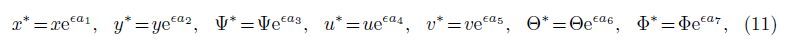

The symmetry groups of (7)-(9) are calculated using the classical Lie group approach. The one-parameter infinitesimal Lie group of transformations leaving (7)-(9) invariant is defined as

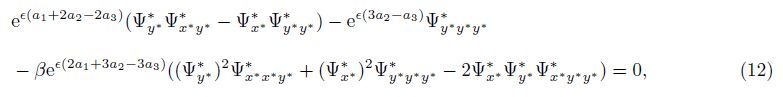

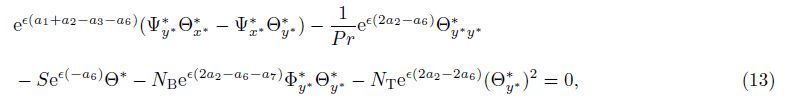

Substituting (11) into (7)-(9),we get

The corresponding similarity variable and functions are

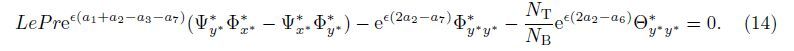

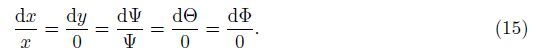

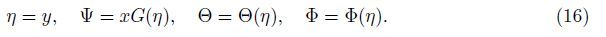

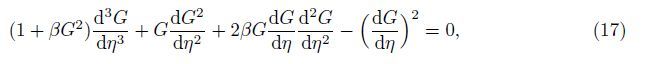

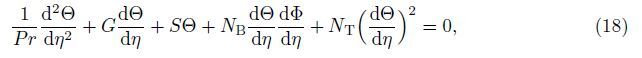

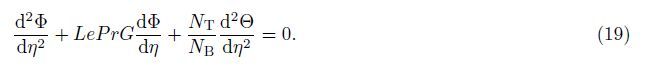

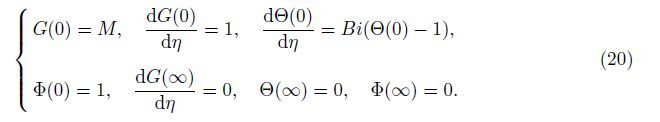

Substituting (16) into (7)-(9) yields the following ordinary equations:

Since (17)-(19) together with the boundary conditions (20) are strongly nonlinear,a numerical treatment will be more appropriate. Thus,these equations are solved numerically by the Bvp4c with MATLAB,and the results are presented graphically and in tables. During the process of numerical computation,the maximum residual error is defined to be less than 10-6.

To test the accuracy of the applied numerical scheme,a comparison of the present results corresponding to -Θ'(0) and -Φ'(0) with those obtained by Makinde and Aziz[6] is presented in Table 1,which shows a favorable agreement. Table 2 presents the numerical values of -Θ'(η) and -Φ'(η) at η = 0 for various values of the Prandtl number Pr,the heat source or sink parameter S,and the suction velocity M when the other parameters are fixed. We can find that both Θ'(0) and Φ'(0) are decreasing functions of the Prandtl number Pr.

In the following section,we focus on the effects of different parameters on the temperature and the concentration. To begin with,we discuss the effects of the Maxwell parameter β on the velocity G'(η). Figure 1 shows that G'(η) is an increasing function of the Maxwell parameter, and the boundary layer thickness increases with the increasing Maxwell parameter β when suction exists. Furthermore,the value of the velocity G'(η) decreases from 1 to zero as η changes from 0 to infinity.

|

| Fig. 1 Effects of Maxwell parameter β on velocity G'(η) |

Figure 2 gives the effects of the Biot number on the temperature and the concentration when there exists the heat source/sink. It can be observed that both the temperature and the concentration are increasing functions of the Biot number. Furthermore,the temperature considering the heat source is higher than that considering the heat sink,which agrees with the practical situation. We also find that the heat source or heat sink has little influence on the concentration.

|

| Fig. 2 Effects of Biot number Bi on temperature Θ(η) and concentration Φ(η) |

Figure 3 shows the influence of the Lewis number on the temperature and concentration distributions. Both are decreasing functions of the Lewis number. We can find that the temperature distribution is considerably different when there exists the heat source/sink. When there exists the heat source,the temperature distribution is higher than that with the heat sink. However,when we consider the influence of the Lewis number on the concentration,the case is different. For the same Lewis number,the concentration with the heat sink is higher than that with the heat source. Furthermore,as the Prandtl number is smaller than 1,the boundary layer becomes thicker obviously not only for the temperature distribution but also for the concentration distribution. The similar phenomenon can also be found in Fig. 4.

|

| Fig. 3 Effects of Lewis number Le on temperature Θ(η) and concentration Φ(η) |

|

| Fig. 4 Effects of Prandtl number Pr on temperature Θ(η) and concentration Φ(η) |

Figure 4 exhibits the temperature and concentration distributions for several values of the Prandtl number. Both the temperature and concentration distributions are decreasing functions of the Prandtl number Pr and trend to zero as they are far away from the wall. However,for the fixed Prandtl number,the temperature with the heat source is higher than that with the heat sink.

Figure 5 illustrates the effects of the Brownian motion parameter on the temperature and the concentration. With the increase of the Brownian motion,the temperature also becomes high. Furthermore,the influence near the wall is obvious. However,it becomes small as the temperature is far away from the wall. When we consider the effect on the concentration,it is similar to the case of the Prandtl number.

|

| Fig. 5 Effects of Brownian motion parameter NB on temperature Θ(η) and concentration Φ(η) |

Figures 6 and 7 show the effects of the thermophoresis parameter NT and the suction velocity on the temperature and concentration distributions. Both the temperature and the concentration are increasing functions of the thermophoresis parameter. Furthermore,no matter there exists the heat source/sink,an extreme point appears near the wall when the thermophoresis parameter is large enough.

|

| Fig. 6 Effects of thermophoresis parameter NT on temperature Θ(η) and concentration Φ(η) |

|

| Fig. 7 Effects of parameter M on temperature Θ(η) and concentration Φ(η) |

Figure 8 shows the influence of large heat source on the temperature distribution. According to the numerical solutions,a new phenomenon that is characterized by the oscillation of the temperature curves is found. This point needs to be explained in the future work.

|

| Fig. 8 Effects of large heat source parameter S on temperature Θ(η) |

Using group-theoretical methods,we obtain the similarity solutions of the convection of a Maxwell fluid over a stretching porous surface with the heat source/sink in the presence of nanoparticles. By determining the transformation group under which the given partial differential equation and its initial and boundary conditions are invariant,we obtain the invariants and the symmetries of this equation. In turn,by the help of these invariants and symmetries, we determine the similarity variables that reduce the number of independent variables. The influence of different physical parameters on the temperature or the concentration is different if we consider the heat source/sink. Furthermore,the suction velocity at the wall also has important influence on the velocity,temperature,and concentration distributions.

| [1] | Eastman, J. A., Phillpot, S. R., Choi, S. U. S., and Keblinski, P. Thermal transport in nanofluids. Annual Review of Materials Research, 34, 219-246(2004) |

| [2] | Kakac, S. and Pramaumjaroenkij, A. Review of convective heat transfer enhancement with nanofluids. International Journal of Heat and Mass Transfer, 52, 3187-3196(2009) |

| [3] | Buongiorno, J. Convective transport in nanofluids. Journal of Heat Transfer, 128, 240-250(2006) |

| [4] | Kuznetsov, A. V. and Nield, D. A. Natural convective boundary-layer flow of a nanofluid past a vertical plate. International Journal of Thermal Sciences, 49, 243-247(2010) |

| [5] | Nield, D. A. and Kuznetsov, A. V. The ChengeMinkowycz problem for natural convective boundary-layer flow in a porous medium saturated by a nanofluid. International Journal of Heat and Mass Transfer, 52, 5792-5795(2009) |

| [6] | Makinde, O. D. and Aziz, A. Boundary layer flow of a nanofluid past a stretching sheet with a convective boundary condition. International Journal of Thermal Sciences, 50, 1326-1332(2011) |

| [7] | Ramesh, G. K. and Gireesha, B. J. Influence of heat source/sink on a Maxwell fluid over a stretching surface with convective boundary condition in the presence of nanoparticles. Ain Shams Engineering Journal, 5, 991-998(2014) |

| [8] | Sadeghy, K. and Sharifi, M. Local similarity solution for the flow of a ‘second-grade’ viscoelastic fluid above a moving plate. International Journal of Non-Linear Mechanics, 39, 1265-1273(2004) |

| [9] | Serdar, B. and Salih Dokuz, M. Three-dimensional stagnation point flow of a second grade fluid towards a moving plate. International Journal of Engineering Science, 44, 49-58(2006) |

| [10] | Siddiqui, A. M., Zeb, A., Ghori, Q. K., and Benharbit, A. M. Homotopy perturbation method for heat transfer flow of a third grade fluid between parallel plates. Chaos Solitons and Fractals, 36, 182-192(2008) |

| [11] | Sajid, M., Ahmad, I., Hayat, T., and Ayub, M. Unsteady flow and heat transfer of a second grade fluid over a stretching sheet. Communications in Nonlinear Science and Numerical Simulation, 14, 96-108(2009) |

| [12] | Hayat, T., Nawaz, M., Sajid, M., and Asghar, S. The effect of thermal radiation on the flow of a second grade fluid. Computers and Mathematics with Applications, 58(2), 369-379(2009) |

| [13] | Si, X. H., Zheng, L. C., and Chao, Y. The flow of a micropolar fluid through a porous channel with expanding or contracting walls. Central European Journal of Physics, 9, 825-834(2011) |

| [14] | Sadeghy, K., Hajibeygi, H., and Taghavi, S. M. Stagnation point flow of upper-convected Maxwell fluids. International Journal of Non-Linear Mechanics, 41, 1242-1247(2006) |

| [15] | Abel, M. S., Tawade, J. V., and Nandeppanavar, M. M. MHD flow and heat transfer for the upper-convected Maxwell fluid over a stretching sheet. Meccanica, 47, 385-393(2012) |

| [16] | Noor, N. F. M. Analysis for MHD flow of a Maxwell fluid past a vertical stretching sheet in the presence of thermophoresis and chemical reaction. World Academy of Science, Engineering and Technology, 64, 1019-1023(2012) |

| [17] | Liu, Q. S., Jian, Y. J., and Yang, L. G. Time periodic electro-osmostic flow of the generalized Maxwell fluids between two micro-parallel plates. Journal of Non-Newtonian Fluid Mechanics, 166, 478-486(2011) |

| [18] | Hayat, T., Fetecau, C., and Sajid, M. On MHD transient flow of a Maxwell fluid in a porous medium and rotating frame. Physics Letters A, 372, 1639-1644(2008) |

| [19] | Nadeem, S., Haq, R. U., and Khan, Z. H. Numerical study of MHD boundary layer fowl of a Maxwell fluid past a stretching sheet in the presence of nanoparticles. Journal of the Taiwan Institute of Chemical Engineers, 45, 121-126(2014) |

| [20] | Olver, J. Application of Lie Groups to Differential Equations, Springer, New York (1989) |

| [21] | Ovsiannikov, L. V. Group Analysis of Differential Equations, Academic Press, New York (1982) |

| [22] | Asghar, S., Jalil, M., Hussan, M., and Turkyilmazoglu, M. Lie group analysis of flow and heat transfer over a stretching rotatingdisk. International Journal of Heat and Mass Transfer, 69, 140-146(2014) |

| [23] | Zhu, J., Zheng, L. C., and Zhang, Z. G. Effects of slip condition on MHD stagnation-point flow over a power-law stretching sheet. Applied Mathematics and Mechanics (English Edition), 31(4), 439-448(2010) DOI 10.1007/s10483-010-0404-z |

| [24] | Abd-el-Malek, M. B., Badrana, N. A., and Hassanb, H. S. Using group theoretic method to solve multi-dimensional diffusion equation. Journal of Computational and Applied Mathematics, 147, 385-395(2002) |

| [25] | Abd-el-Malek, M. B. and Aminb, A. M. Lie group analysis of nonlinear inviscid flows with a free surface under gravity. Journal of Computational and Applied Mathematics, 258, 17-29(2014) |

| [26] | Boutros, Y. Z., Abd-el-Malek, M. B., Badran, N. A., and Hassan, H. S. Lie-group method solution for two-dimensional viscous flow between slowly expanding or contracting walls with weak permeability. Applied Mathematical Modelling, 31, 1092-1108(2007) |

| [27] | Hamad, M. A. A. Analytical solution of natural convection flow of a nanofluid over a linearly stretching sheet in the presence of magnetic field. International Communications in Heat and Mass Transfer, 38, 487-492(2011) |

| [28] | Das, K. Lie group analysis for nanofluid flow past a convectively heated stretching surface. Applied Mathematics and Computation, 221, 547-557(2013) |

| [29] | Ramesh, G. K. and Gireesha, B. J. Influence of heat soure/sink on aMaxwell fluid over a stretching surface with convective boundary condition in the presence of nanoparticles. Ain Shams Engineering Journal, 5, 991-998(2014) |

2016, Vol. 37

2016, Vol. 37