1 Introduction

Low thermal conductivity is a primary limitation in the development of energy coefficient

heat transfer fluids required in many industrial and commercial applications. To get rid of such

issue,a new class of nanofluids has been developed. These fluids are the mixtures of traditional

fluids with nanoparticles. It was experimentally demonstrated that the resulting heat

transfer nanofluids have significantly higher thermal conductivity than the traditional fluids.

The nanofluids are the material through traditional liquids subject to suspended nanoparticles.

Metallic or nonmetallic nanometer sized particles are used as the nanoparticles. In particular,

the nanofluids have a pivotal role in advanced cooling systems,micro/nano electromechanical

devices,and thermal management systems via evaporators,heat exchangers,and industrial

cooling applications. Several researchers at present are now engaged to model and simulate

the flows of nanofluids. Some recent contributions in this direction may be found in Refs.

[1, 2, 3, 4, 5, 6, 7, 8, 9, 10] and the references therein. Moreover,it is well recognized that several fluids in industry

and engineering are non-Newtonian in nature. The well-known Nevier-Stokes equations do not

predict the rheological characteristics of non-Newtonian materials. Further,one constitutive relationship cannot describe the flow behaviors of all non-Newtonian fluids. Hence,several models

of non-Newtonian fluids were used[11, 12, 13, 14, 15]. The Casson fluid[16] is one of the non-Newtonian

materials predicting the shear thinning liquid (e.g.,blood,Jelly,concentrated fruit juices,etc).

It has been noted that not much has been reported about the flow of non-Newtonian fluids

with nanoparticles. Hence,the main aim of the present paper is to address the flow of the

Casson fluid in the presence of nanoparticles. The Brownian motion and thermophoretic effects

are presented. The flow considered is due to the stretching cylinder. The nonlinear problem is

computed and studied.

2 Problem development

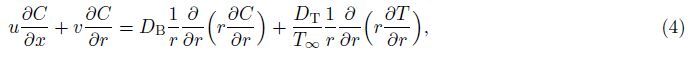

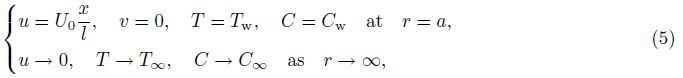

The axisymmetric flow of an incompressible Casson fluid with nanoparticles is examined.

The behaviors of the Brownian motion and thermophoresis are also considered. The stretchable

cylinder is along the horizontal axis,i.e.,the x-axis. Here,the r-axis is taken along the radial

direction. The velocity,temperature,and concentration fields through the boundary layer

approximations satisfy the following equations:

where

u and

v represent the velocity components along the

x- and

r-directions,respectively,

U0 is the reference velocity,

β =${{{\mu _B}\sqrt {2{\pi _c}} } \over {{\tau _r}}}$ is the material parameter,in which

μB is the plastic

dynamic viscosity,

τr is the yield stress of fluid,and πc

is the critical value of this product

based on the non-Newtonian model,

l is the characteristic length,τ = (

ρc)

p/(

ρc)

f is the ratio

between the effective heat capacity of the nanoparticle material and heat capacity of the fluid

with

ρ being the density,

DB is the Brownian diffusion coefficient,

DT is the thermophoretic

diffusion coefficient,

σ is the thermal diffusivity of the fluid,

cp is the specific heat at the constant

pressure,

Cw is the concentration susceptibility,

Tw is the wall temperature,

ν is the kinematic

viscosity,and

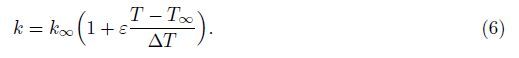

k is the variable thermal conductivity of the fluid defined as

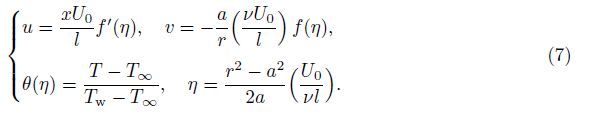

We introduce the following nondimensional quantities:

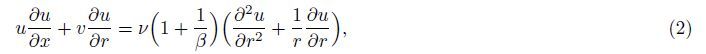

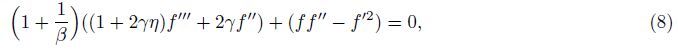

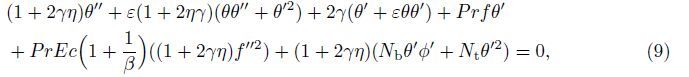

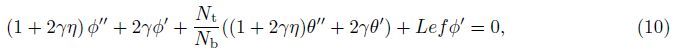

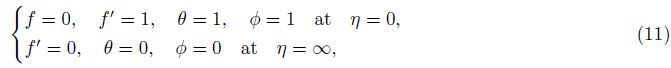

By Eq. (7),Eq. (1) is identically satisfied,and Eqs. (2)-(5) yield

where

γ =$\sqrt {{{lv} \over {{a^2}{U_0}}}} $is a curvature parameter,

Pr =${\nu \over \sigma }$ is the Prandtl number,

Nb=τ${{{D_B}} \over \nu }$ (

Cw-

C∞)

is the Brownian motion parameter,N

t =${{\tau {D_T}\left( {{T_W} - {T_\infty }} \right)} \over {{T_\infty }\nu }}$is the thermophoretic parameter,

Ec = ${{U_0^2{{\left( {x/l} \right)}^2}} \over {{c_p}\left( {{T_W} - {T_\infty }} \right)}}$is the Eckert number,and

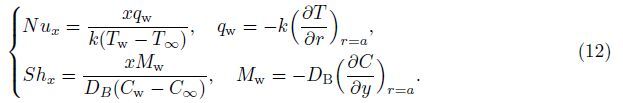

Le =${\nu \over {{D_B}}}$ is the Lewis number. The local Nusselt number

Nux and the Sherwood number

Shx are defined as

The dimensionless form of the local Nusselt number

Nux is

The dimensionless form of the Sherwood number

Shx is given by

3 Homotopy analysis solutions

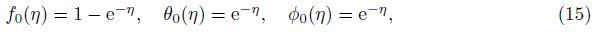

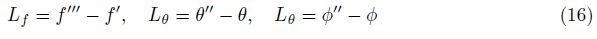

The initial approximations and auxiliary linear operators are chosen in the forms of

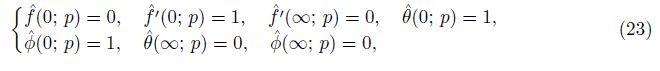

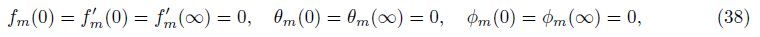

subject to

where

Ci (

i = 1,2,· · · ,7) are the arbitrary constants determined from the boundary conditions.

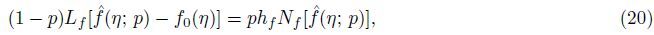

If

p ∈ [0,1] denotes an embedding parameter,and

hf,

hθ,and

hφ are the non-zero auxiliary

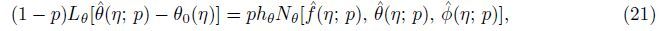

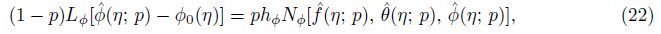

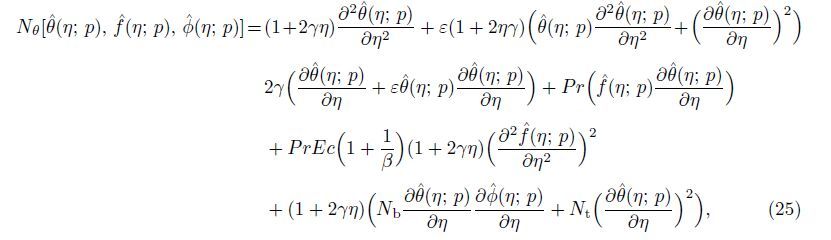

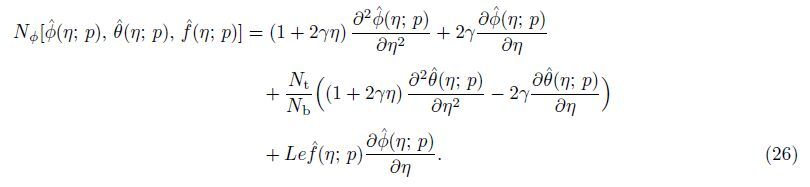

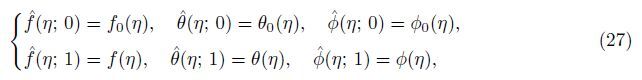

parameters,then the zeroth-order deformation problems are

where

Nf,

Nθ,and

Nφ are the nonlinear operators defined by

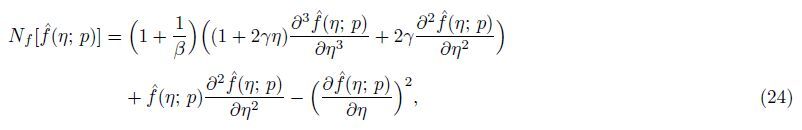

When

p = 0 and

p = 1,

and when

p varies from 0 to 1,

f(

η;

p),

θ(

η;

p),and

φ(

η;

p) vary from

f0(

η),

θ0(

η),and

φ0(

η)

to

f(

η),

θ(

η),and

φ(

η),respectively. Now,

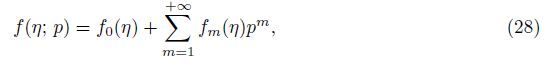

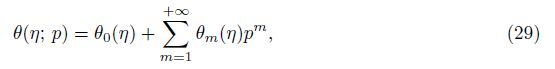

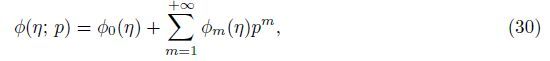

f,

θ,and

φ in Taylor’s series can be elaborated as

follows:

where the convergence depends upon

hf,

hθ and

hφ. By proper choice of

hf,

hθ,and

hφ,the

series (28)-(30) converge for

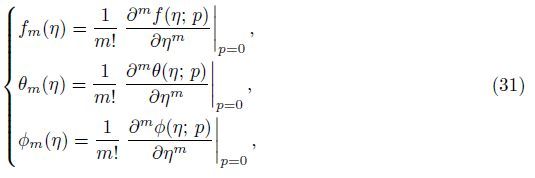

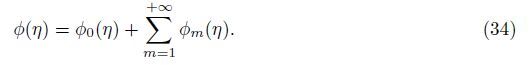

p = 1. Hence,

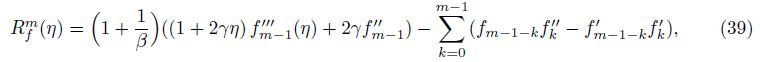

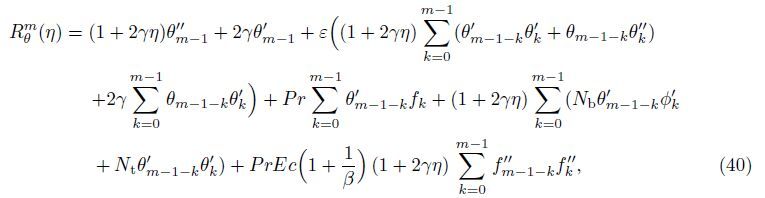

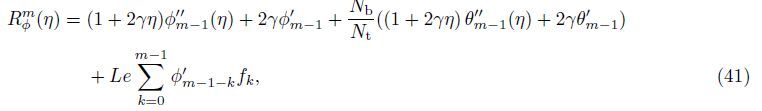

The mth-order deformation problems are given by

The general solutions of Eqs. (35)-(37) are

where f

m*,

θm*,and

φm* are the special solutions of Eqs. (43)-(45).

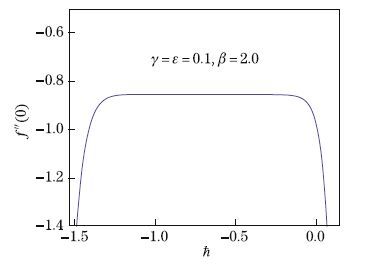

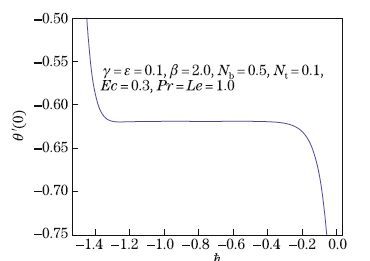

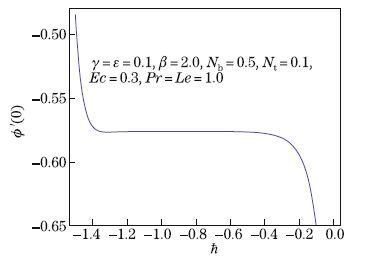

We know that the homotopy analysis method (HAM)[16, 17, 18, 19, 20] solution highly depends upon

the non-zero auxiliary parameter ħ which helps us to adjust and control the convergence region.

Therefore,we draw the ħ-curves for f''(0),θ'(0),and φ'(0). Figures 1-3 depict the ħ-curves for

different values of embedded parameters. The suitable range of ħf is -1.2 < ħf < -0.2,for ħθ,it is -0.5 < ħθ < -0.8,and for ħφ,it is -0.8 < ħφ < -1.2. It is found that the HAM solutions

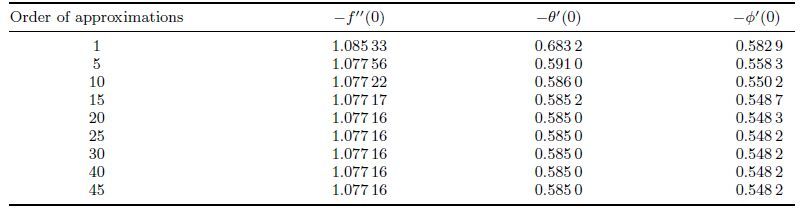

converge entirely when ħf = -0.8,ħθ = -1.2,and hφ = -1.2. Table 1 shows the convergence of

series solutions. It is evident that the 20th-order estimations are enough for convergent series

solutions.

Table 1 Convergence of HAM solutions for different orders of approximations

4 Results and discussion

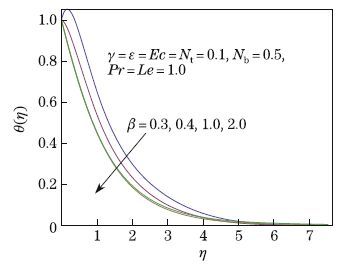

This section discloses the salient features of different physical quantities involved in the

temperature and concentration fields. The temperature profile is drawn in Fig. 4 for various

values of Casson fluid parameter β. The temperature profile decreases with the increasing η

for given values of β. It is shown that the Casson fluid parameter is inversely proportional

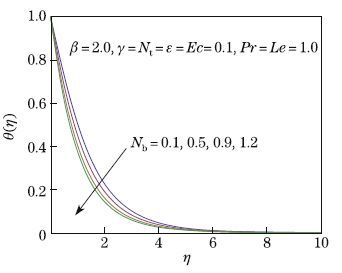

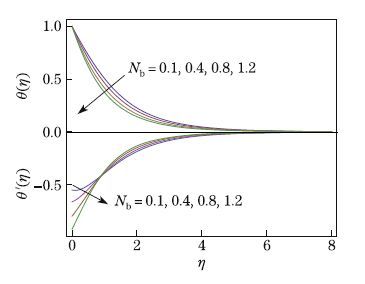

to the yield stress. The variation of the temperature with η is calculated for different values of Brownian motion parameter Nb in Fig. 5. When Nb increases,both the temperature and

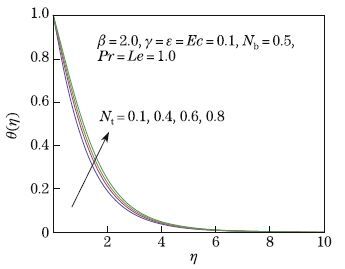

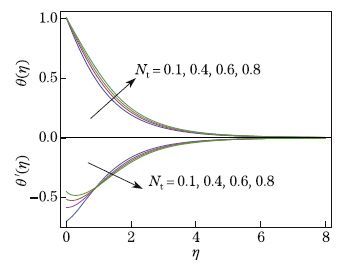

the thermal boundary layer thickness decrease. Figure 6 depicts the effect of thermophoretic

parameterNton the temperature profile. This figure shows thatNtenhances the temperature

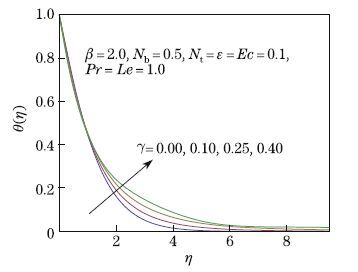

field. Figure 7 plots the influence of γ on the temperature field. The effect of γ near the wall is

almost negligible,while when η > 1,the temperature increases. Figure 8 explains the variation

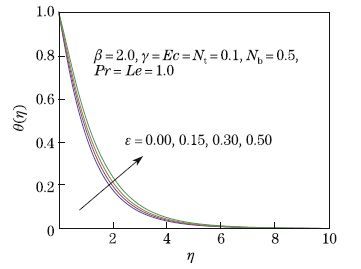

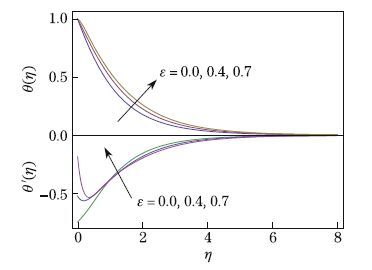

of variable thermal conductivity parameter ε on the temperature profile. It is noted that

θ(η) for the constant thermal conductivity case is less than the variable thermal conductivity.

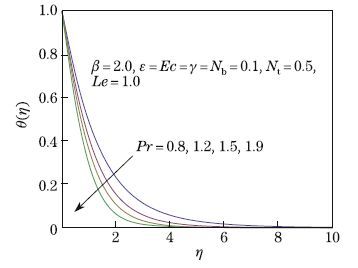

Figure 9 describes the variation of Pr on the temperature field. This figure illustrates that the

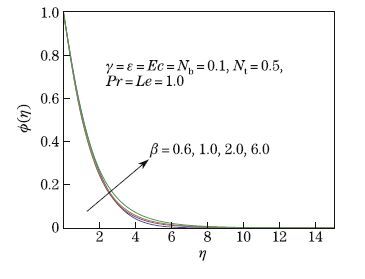

temperature field decreases when Pr increases. The effect of the Casson fluid parameter β on

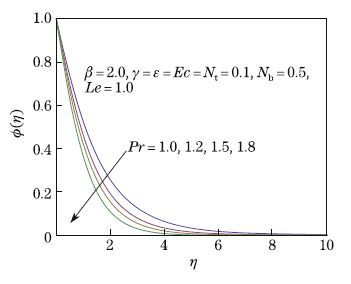

φ(η) is shown in Fig. 10. This indicates that φ(η) is an increasing function of the Casson fluid

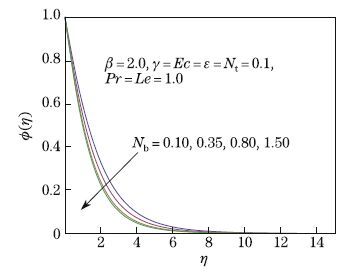

parameter β. Figure 11 displays the influence of the Brownian motion parameter Nb on φ(η).

The concentration field decreases very slowly when the Brownian motion parameter increases.

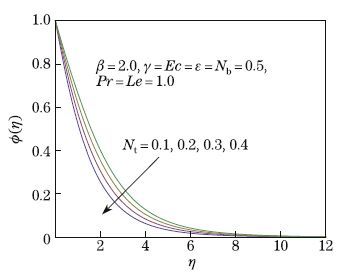

The enhancement in the thermophoretic parameterNtleads to an increase in the concentration

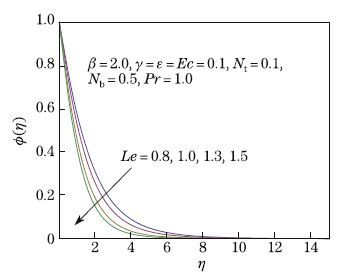

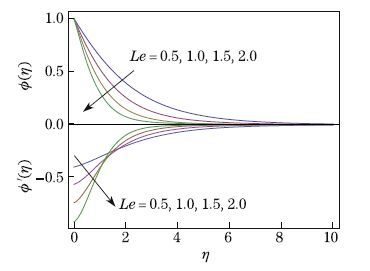

field. Also,the boundary layer thickness is more pronounced (see Fig. 12). The effect of Le

is depicted in Fig. 13. The concentration field and the associated boundary layer thickness

are decreasing functions of Le. The Prandtl and Lewis numbers have similar effects on the

concentration (see Fig. 14). Figure 15 illustrates the impact of temperature and temperature

gradient for different values of Nt. The temperature increases for larger values of Nt,whereas

the temperature gradient increases most rapidly near the wall,but when η > 1,it decays

very slowly and then vanishes far away. The temperature gradient decreases near the cylinder

surface when the fluid thermal conductivity increases (see Fig. 16). Figures 17 and 18 present

the effects of Nb and Le on the concentration and the concentration gradient,respectively. For

both parameters,the temperature and the temperature gradient decrease.

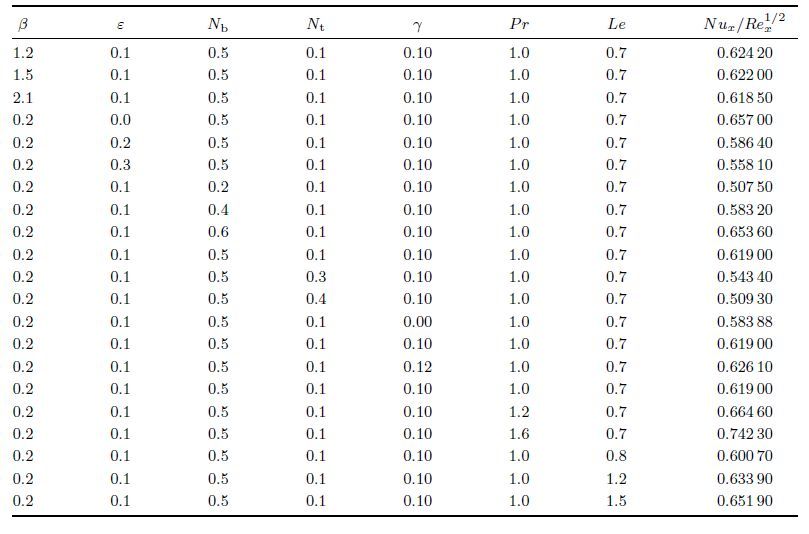

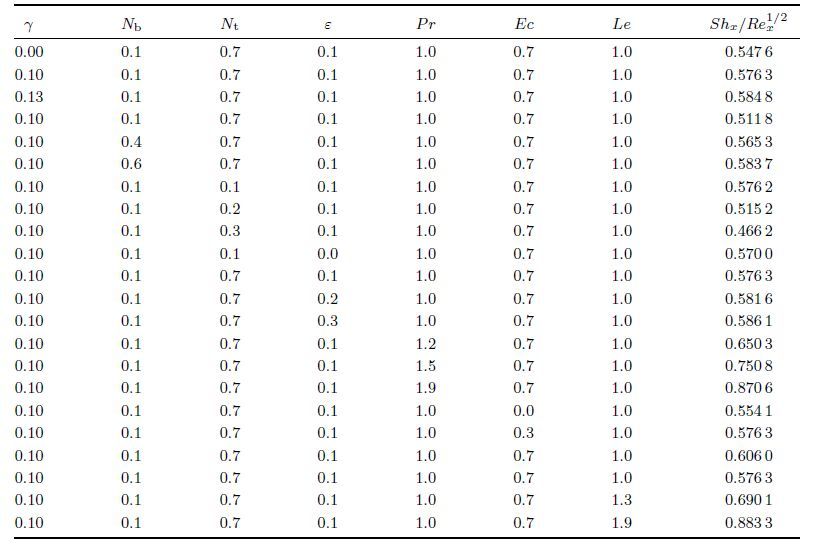

Table 2 depicts the numerical values of local Nusselt number for different values of β,ε,Nb,γ,

Pr,Le,and Nt. The increase in Nb,Pr,γ,and Le enhances the local Nusselt number. It is

also observed from this table that for larger values of β,ε,and Nt,the local Nusselt number

decreases. The numerical values of local Sherwood number are displayed in Table 3. The local Sherwood number at the wall decreases for larger Nb and Nt. The enhancement in β,ε,Pr,Ec,

and Le yields an increase in the local Sherwood number.

Table 2 Values of local Nusselt number Nux/Rex1/2

for different parameters

Table 3 Values of local Sherwood number Shx/Rex1/2for different parameters

5 Conclusions

This article addresses the flow of the Casson fluid with nanoparticles. The resulting problems

are computed successfully. It is found that the temperature and the thermal boundary layer

thickness are increasing functions of ε and Nt. However,Nb and γ have opposite behavior on

the temperature profile. Variable thermal conductivity enhances the fluid temperature,while

it decreases θ'(0) from the wall. Both the local Nusselt and local Sherwood numbers increase

with Le,whereas Nt has the opposite effect.

2016, Vol. 37

2016, Vol. 37