Applied Mathematics and Mechanics (English Edition) ›› 2025, Vol. 46 ›› Issue (7): 1315-1330.doi: https://doi.org/10.1007/s10483-025-3270-9

Previous Articles Next Articles

Qi WANG1,2, Li DING1,2, Shuo WANG1,2, Danping RUAN3, Yuanzhi XU4, Yanshu CHU1, D. AROLA5, Bingbing AN1,2,6, Dongsheng ZHANG1,2,6,†( )

)

Received:2025-02-28

Revised:2025-05-18

Published:2025-06-30

Contact:

Dongsheng ZHANG, E-mail: donzhang@staff.shu.edu.cnSupported by:2010 MSC Number:

Qi WANG, Li DING, Shuo WANG, Danping RUAN, Yuanzhi XU, Yanshu CHU, D. AROLA, Bingbing AN, Dongsheng ZHANG. A toughening strategy of the glass composite with a laminated interlocking feature. Applied Mathematics and Mechanics (English Edition), 2025, 46(7): 1315-1330.

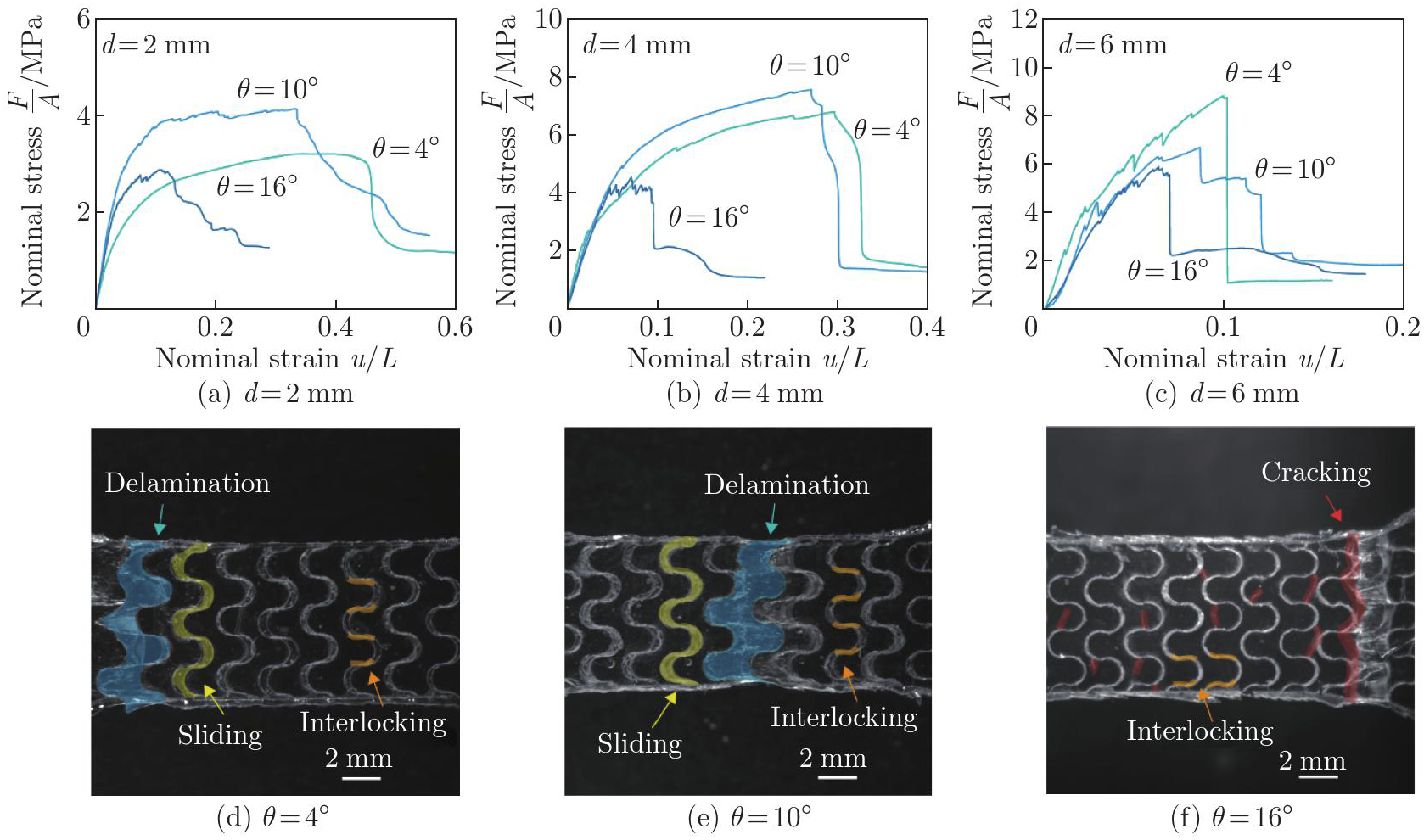

Fig. 3

Effects of the interlocking angle on the tensile response of GPIS specimens: nominal stress-strain curves of GPIS specimens with θ=4∘, 10°, and 16° with (a) d=2 mm, (b) d=4 mm, and (c) d=6 mm; associated deformation mechanisms of GPIS specimens (d=4 mm) with (d) θ=4∘, (e) θ=10∘, and (f) θ=16∘ (color online)"

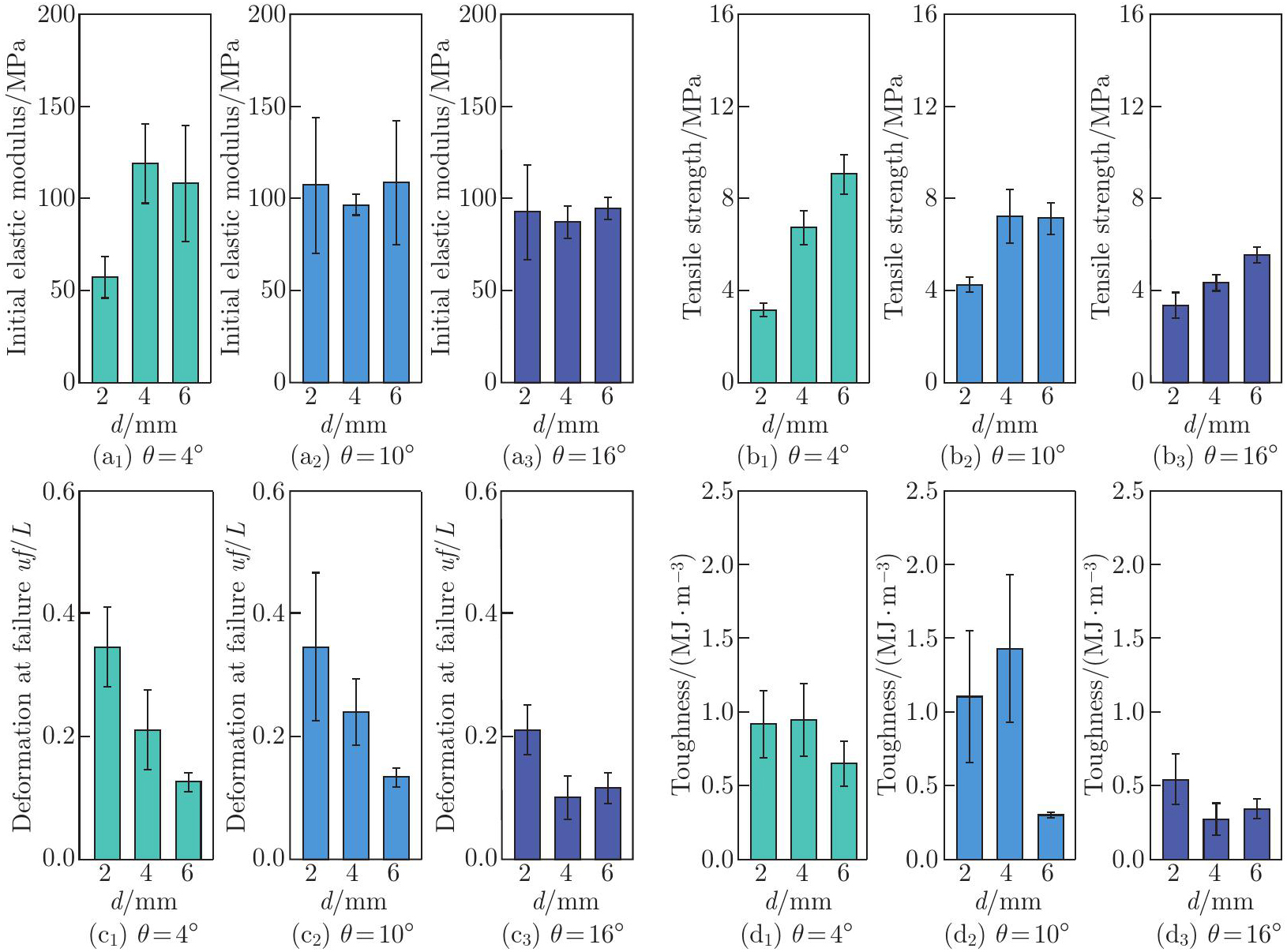

Fig. 5

The overall tensile performance of the GPIS specimens: (a1)–(a3) initial elastic modulus, (b1)–(b3) tensile strength, (c1)–(c3) deformation at failure, and (d1)–(d3) toughness calculated by energy absorption based on the failure criterion that the nominal stress drops below the yielding strength of EVA (2 MPa) (color online)"

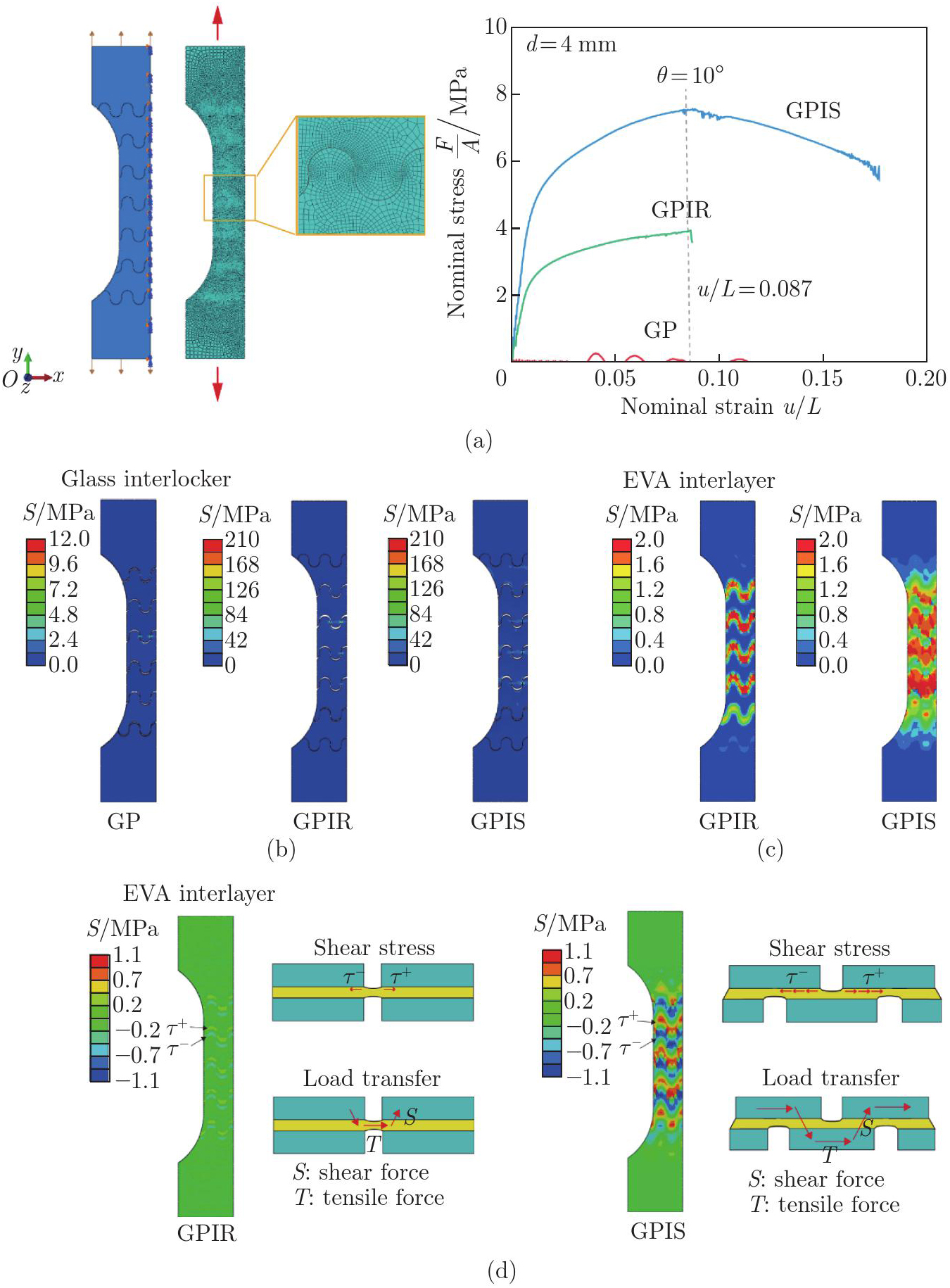

Fig. 6

Numerical results of the tensile tests: (a) 3D finite element modeling and stress-strain curves, (b) von Mises stress distributions in the glass interlockers, (c) von Mises stress distributions in the interlayer, and (d) shear stress distributions in the interlayer at u/L=0.087 (color online)"

| [1] | WEGST, U. G. K., BAI, H., SAIZ, E., TOMSIA, A. P., and RITCHIE, R. O. Bioinspired structural materials. Nature Materials, 14, 23–36 (2015) |

| [2] | RITCHIE, R. O. The conflicts between strength and toughness. Nature Materials, 10, 817–822 (2011) |

| [3] | MEYERS, M. A., MCKITTRICK, J., and CHEN, P. Y. Structural biological materials: critical mechanics-materials connections. Science, 339, 773–779 (2013) |

| [4] | KOESTER, K. J., AGER, J. W., and RITCHIE, R. O. The true toughness of human cortical bone measured with realistically short cracks. Nature Materials, 7, 672–677 (2008) |

| [5] | CHEN, I. H., YANG, W., and MEYERS, M. A. Leatherback sea turtle shell: a tough and flexible biological design. Acta Biomaterialia, 28, 2–12 (2015) |

| [6] | ACHRAI, B. and WAGNER, H. D. Micro-structure and mechanical properties of the turtle carapace as a biological composite shield. Acta Biomaterialia, 9, 5890–5902 (2013) |

| [7] | BARTHELAT, F., TANG, H., ZAVATTIERI, P. D., LI, C. M., and ESPINOSA, H. D. On the mechanics of mother-of-pearl: a key feature in the material hierarchical structure. Journal of the Mechanics and Physics of Solids, 55, 306–337 (2007) |

| [8] | BARTHELAT, F. Architectured materials in engineering and biology: fabrication, structure, mechanics and performance. International Materials Reviews, 60, 413–430 (2015) |

| [9] | MEYERS, M. A., CHEN, P. Y., LIN, A. Y. M., and SEKI, Y. Biological materials: structure and mechanical properties. Progress in Materials Science, 53, 1–206 (2008) |

| [10] | FRATZL, P., KOLEDNIK, O., FISCHER, F. D., and DEAN, M. N. The mechanics of tessellations — bioinspired strategies for fracture resistance. Chemical Society Reviews, 45, 252–267 (2016) |

| [11] | BARTHELAT, F., YIN, Z., and BUEHLER, M. J. Structure and mechanics of interfaces in biological materials. Nature Reviews Materials, 1, 16007 (2016) |

| [12] | BARTHELAT, F. and RABIEI, R. Toughness amplification in natural composites. Journal of the Mechanics and Physics of Solids, 59, 829–840 (2011) |

| [13] | BARTHELAT, F. Designing nacre-like materials for simultaneous stiffness, strength and toughness: optimum materials, composition, microstructure and size. Journal of the Mechanics and Physics of Solids, 73, 22–37 (2014) |

| [14] | BEGLEY, M. R., PHILIPS, N. R., COMPTON, B. G., WILBRINK, D. V., RITCHIE, R. O., and UTZ, M. Micromechanical models to guide the development of synthetic ‘brick and mortar’ composites. Journal of the Mechanics and Physics of Solids, 60, 1545–1560 (2012) |

| [15] | ESPINOSA, H. D., RIM, J. E., BARTHELAT, F., and BUEHLER, M. J. Merger of structure and material in nacre and bone — perspectives on de novo biomimetic materials. Progress in Materials Science, 54, 1059–1100 (2009) |

| [16] | JACKSON, A. P., VINCENT, J. F. V., TURNER, R. M., and ALEXANDER, R. M. The mechanical design of nacre. Proceedings of the Royal Society of London. Series B, 234, 415–440 (1988) |

| [17] | WANG, R. Z., SUO, Z. G., EVANS, A. G., YAO, N., and AKSAY, I. A. Deformation mechanisms in nacre. Journal of Materials Research, 16, 2485–2493 (2001) |

| [18] | SONG, F. and BAI, Y. L. Effects of nanostructures on the fracture strength of the interfaces in nacre. Journal of Materials Research, 18, 1741–1744 (2003) |

| [19] | CUI, S. K., YANG, Z. Y., and LU, Z. X. An analytical model for the bio-inspired nacreous composites with interlocked “brick-and-mortar” structures. Composites Science and Technology, 193, 108131 (2020) |

| [20] | BONDERER, L. J., STUDART, A. R., and GAUCKLER, L. J. Bioinspired design and assembly of platelet reinforced polymer films. Science, 319, 1069–1073 (2008) |

| [21] | YIN, Z., HANNARD, F., and BARTHELAT, F. Impact-resistant nacre-like transparent materials. Science, 364, 1260–1263 (2019) |

| [22] | TAN, G. Q., ZHANG, J., ZHENG, L., JIAO, D., LIU, Z. Q., ZHANG, Z. F., and RITCHIE, R. O. Nature-inspired nacre-like composites combining human tooth-matching elasticity and hardness with exceptional damage tolerance. Advanced Materials, 31, e1904603 (2019) |

| [23] | LI, Y. N., ORTIZ, C., and BOYCE, M. C. Bioinspired, mechanical, deterministic fractal model for hierarchical suture joints. Physical Review E, 85, 031901 (2012) |

| [24] | LI, Y. N., ORTIZ, C., and BOYCE, M. C. A generalized mechanical model for suture interfaces of arbitrary geometry. Journal of the Mechanics and Physics of Solids, 61, 1144–1167 (2013) |

| [25] | LI, Y. N., ORTIZ, C., and BOYCE, M. C. Stiffness and strength of suture joints in nature. Physical Review E, 84, 062904 (2011) |

| [26] | JIANG, P., ZHANG, S. H., YANG, H., and LI, Y. Suture interface inspired self-recovery architected structures for reusable energy absorption. ACS Applied Materials & Interfaces, 15, 43102–43110 (2023) |

| [27] | MIURA, T., PERLYN, C. A., KINBOSHI, M., OGIHARA, N., KOBAYASHI-MIURA, M., MORRISS-KAY, G. M., and SHIOTA, K. Mechanism of skull suture maintenance and interdigitation. Journal of Anatomy, 215, 642–655 (2009) |

| [28] | LEE, N., HORSTEMEYER, M. F., RHEE, H., NABORS, B., LIAO, J., and WILLIAMS, L. N. Hierarchical multiscale structure-property relationships of the red-bellied woodpecker (melanerpes carolinus) beak. Journal of the Royal Society Interface, 11, 20140274 (2014) |

| [29] | LIN, E., LI, Y. N., WEAVER, J. C., ORTIZ, C., and BOYCE, M. C. Tunability and enhancement of mechanical behavior with additively manufactured bio-inspired hierarchical suture interfaces. Journal of Materials Research, 29, 1867–1875 (2014) |

| [30] | CORDISCO, F. A., ZAVATTIERI, P. D., HECTOR, L. G., and CARLSON, B. E. Mode I fracture along adhesively bonded sinusoidal interfaces. International Journal of Solids and Structures, 83, 45–64 (2016) |

| [31] | LIN, E., LI, Y. N., ORTIZ, C., and BOYCE, M. C. 3D printed, bio-inspired prototypes and analytical models for structured suture interfaces with geometrically-tuned deformation and failure behavior. Journal of the Mechanics and Physics of Solids, 73, 166–182 (2014) |

| [32] | MIRKHALAF, M., DASTJERDI, A. K., and BARTHELAT, F. Overcoming the brittleness of glass through bio-inspiration and micro-architecture. Nature Communications, 5, 3166 (2014) |

| [33] | MALIK, I. A. and BARTHELAT, F. Toughening of thin ceramic plates using bioinspired surface patterns. International Journal of Solids and Structures, 97-98, 389–399 (2016) |

| [34] | KATZ, Z., YAZDANI SARVESTANI, H., GHOLIPOUR, J., and ASHRAFI, B. Bioinspired hierarchical ceramic sutures for multi-modal performance. Advanced Materials Interfaces, 10, 2300098 (2023) |

| [35] | MALIK, I. A., MIRKHALAF, M., and BARTHELAT, F. Bio-inspired “jigsaw”-like interlocking sutures: modeling, optimization, 3D printing and testing. Journal of the Mechanics and Physics of Solids, 102, 224–238 (2017) |

| [36] | MALIK, I. A. and BARTHELAT, F. Bioinspired sutured materials for strength and toughness: pullout mechanisms and geometric enrichments. International Journal of Solids and Structures, 138, 118–133 (2018) |

| [37] | MIRKHALAF, M. and BARTHELAT, F. Design, 3D printing and testing of architectured materials with bistable interlocks. Extreme Mechanics Letters, 11, 1–7 (2017) |

| [38] | LI, X. R., JIANG, P. F., NIE, M. H., LIU, Z. L., LIU, M. Q., QIU, Y. M., CHEN, Z. K., and ZHANG, Z. H. Enhanced strength-ductility synergy of laser additive manufactured stainless steel/Ni-based superalloy dissimilar materials characterized by bionic mechanical interlocking structures. Journal of Materials Research and Technology, 26, 4770–4783 (2023) |

| [39] | GAO, C., HASSELDINE, B. P. J., LI, L., WEAVER, J. C., and LI, Y. N. Amplifying strength, toughness, and auxeticity via wavy sutural tessellation in plant seedcoats. Advanced Materials, 30, e1800579 (2018) |

| [40] | SIEGMUND, T., BARTHELAT, F., CIPRA, R., HABTOUR, E., and RIDDICK, J. Manufacture and mechanics of topologically interlocked material assemblies. Applied Mechanics Reviews, 68, 040803 (2016) |

| [41] | WANG, Q., DING, L., WANG, S., AROLA, D., AN, B. B., and ZHANG, D. S. Strong and tough glass composites with a partially segmented micro-architecture. Composites Science and Technology, 244, 110301 (2023) |

| [42] | AMINI, A., TIRGAR, P., BAHMANI, A., JAFARI, M., SIAJ, M., BARTHELAT, F., and EHRLICHER, A. Nacreous glass composites with superior performance engineered through mechanical vibration and silanization. Advanced Functional Materials, 34, 2405008 (2024) |

| [43] | YIN, Z., DASTJERDI, A., and BARTHELAT, F. Tough and deformable glasses with bioinspired cross-ply architectures. Acta Biomaterialia, 75, 439–450 (2018) |

| [44] | ZHANG, X., WU, K. J., NI, Y., and HE, L. H. Anomalous inapplicability of nacre-like architectures as impact-resistant templates in a wide range of impact velocities. Nature Communications, 13, 7719 (2022) |

| [45] | WANG, W. Z., SUN, Y. P., LU, Y. Y., WANG, J. P., CAO, Y., and ZHANG, C. Tensile behavior of bio-inspired hierarchical suture joint with uniform fractal interlocking design. Journal of the Mechanical Behavior of Biomedical Materials, 113, 104137 (2021) |

| [46] | BARTHELAT, F., DASTJERDI, A. K., and RABIEI, R. An improved failure criterion for biological and engineered staggered composites. Journal of the Royal Society Interface, 10, 20120849 (2013) |

| [47] | CHINTAPALLI, R. K., BRETON, S., DASTJERDI, A. K., and BARTHELAT, F. Strain rate hardening: a hidden but critical mechanism for biological composites? Acta Biomaterialia, 10, 5064–5073 (2014) |

| [48] | JI, B. H. and GAO, H. J. Mechanical properties of nanostructure of biological materials. Journal of the Mechanics and Physics of Solids, 52, 1963–1990 (2004) |

| [49] | AN, B., SUN, W., and ZHANG, D. S. Role of soft bi-layer coating on the protection of turtle carapace. Journal of Biomechanics, 126, 110618 (2021) |

| [50] | JALALVAND, M., CZÉL, G., FULLER, J. D., WISNOM, M. R., CANAL, L. P., GONZÁLEZ, C. D., and LLORCA, J. Energy dissipation during delamination in composite materials — an experimental assessment of the cohesive law and the stress-strain field ahead of a crack tip. Composites Science and Technology, 134, 115–124 (2016) |

| [51] | YANG, H., SINHA, S. K., FENG, Y., MCCALLEN, D. B., and JEREMIĆ, B. Energy dissipation analysis of elastic-plastic materials. Computer Methods in Applied Mechanics and Engineering, 331, 309–326 (2018) |

| [1] | N. SHAHVEISI, S. FELI. Dynamic and electrical responses of a curved sandwich beam with glass reinforced laminate layers and a pliable core in the presence of a piezoelectric layer under low-velocity impact [J]. Applied Mathematics and Mechanics (English Edition), 2024, 45(1): 155-178. |

| [2] | Haoran BAI, Zhanyu WANG, Sangyu LUO, Zhaoliang QU, Daining FANG. A modified single edge V-notched beam method for evaluating surface fracture toughness of thermal barrier coatings [J]. Applied Mathematics and Mechanics (English Edition), 2023, 44(5): 693-710. |

| [3] | Shan XIA, Linghui HE. Buckling morphology of glassy nematic films with staggered director field [J]. Applied Mathematics and Mechanics (English Edition), 2023, 44(11): 1841-1852. |

| [4] | Dong WU, Yixing HUANG, Ming LEI, Zeang ZHAO, Xiaogang GUO, Daining FANG. Stiffness and toughness of soft/stiff suture joints in biological composites [J]. Applied Mathematics and Mechanics (English Edition), 2022, 43(10): 1469-1484. |

| [5] | Zhi-hong ZHOU;Yao-long HE;Hong-jiu HU;Feng ZHAO;Xiao-long ZHANG. Creep performance of PVC aged at temperature relatively close to glass transition temperature [J]. Applied Mathematics and Mechanics (English Edition), 2012, 33(9): 1129-1136. |

| [6] | ZHOU Hua-min;SUN Qiang;XI Guo-dong;LI De-qun. NUMERICAL PREDICTION OF PROCESS-INDUCED RESIDUAL STRESSES IN GLASS BULB PANEL [J]. Applied Mathematics and Mechanics (English Edition), 2006, 27(9): 1197-1206 . |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

Email Alert

Email Alert RSS

RSS